1-866-777-1360 M-F 6am - 4pm PST Mon-Fri, 06:00 - 16:00 (UTC-8)

Get Catalog | Get Free Samples

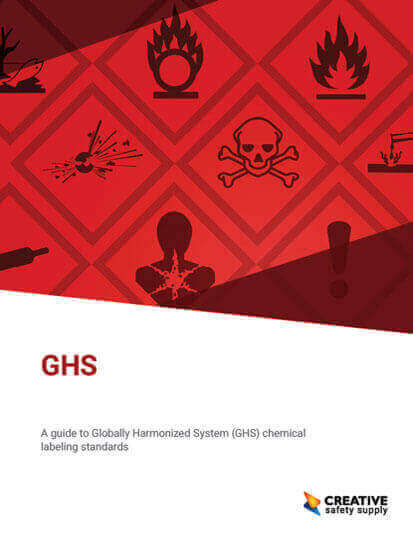

The Definitive Guide to Globally Harmonized System (GHS) Labeling

- Custom GHS Labels

- GHS Label Printers

- GHS Pictogram Stickers

- MSDS Labels

- GHS Posters

What Does GHS Stand For?

Ghs training, 2019 changes: ghs revision 8, signal words, ghs pictograms, hazard statement, precautionary statement, safety data sheets, additional ghs labeling facts:.

The Globally Harmonized System, also known as GHS, is a standard that has been adopted by companies, governments, universities and other institutions around the world. Recently aligned with OSHA’s Hazard Communication Standard, the newly combined GHS and HCS system is focused on creating a consistent way of classifying chemical hazards. The improvements made to these standards also aim to reduce trade barriers to those who deal with these substances regularly.

This guide is not meant to replace any official training courses or compliance manuals. Instead, it will help give more of a high-level overview of what GHS is and its necessary compliance requirements.

The Globally Harmonized System of Classification and Labeling of Chemicals was initially created by the United Nations in 1992 to improve workplace safety. Since implementing this standard globally, miscommunications that often result in serious accidents have been much easier to avoid. Part of this is due to the fact that costly and error ridden re-labeling efforts are no longer needed when countries create and transport hazardous chemicals from one place to the next with this consistent labeling standard.

For most companies, GHS became important back on March 26, 2012 when OSHA published their final rule that revised the old Hazard Communication Standard to be in line with GHS. The update impacted millions of workers throughout a wide range of different workplaces on subjects such as the classification of hazards, GHS labeling requirements, safety data sheets, and employee training.

GHS and OSHA Standards

Today, GHS compliance is necessary for all facilities to avoid fines or other penalties from OSHA. OSHA requires every company that deals with hazardous chemicals to have a hazard communication program in place. This communication program includes several steps that build an effective and safe environment for employees, those include:

- Learning about the relevant standards

- Implementing a written hazard communication program

- Following GHS label requirements

- Maintaining SDSs

- Training employees

- Periodically reassessing the hazard communication program

Just like any other improvement strategy, if the employees don't understand or follow it, then it will be virtually useless. With this in mind, developing a good training program to help ensure everyone is on the same page is essential.

If onsite training is an option, make sure to use a reliable manual or GHS guide to ensure all the most important topics are covered. Once the bulk of training is completed for new hires the next step is to keep GHS standards on everyone’s minds. The following are some ideas on how this can be done:

- Follow up classes - Offering annual 'refresher' classes will help keep the information fresh.

- Updated handouts - Whenever there is an update to the GHS standards or how the facility uses them, make sure detailed explanations are given to employees.

- GHS posters - Putting up GHS posters throughout the facility is a great way to have constant visual reminders for those working in the area.

In July of 2019, the 8th revised edition of GHS was published . These new changes include:

- The classification criteria for aerosols. Under the new edition, aerosols will be classified in three categories for their hazard class. They are determined based on their flammable properties, heat of combustion, and applicable test results.

- A new hazard category. It is now possible to identify and classify chemicals under pressure, Information on criteria, as well as corresponding signal words, pictograms, and hazard statements, are provided.

- New labeling examples for sets or kits. There are now examples for set/kit labeling for situations in which there is not enough space to relate the required information.

- New precautionary pictograms. This edition includes two new pictograms developed by AISE and JSDA. The pictograms convey the meaning of precautionary statement P102: “Keep out of reach of children.”

- Other hazards not previously classified. An altered Annex 11 provides advice on dust explosion hazards. It covers potential factors, identification, mitigation, prevention, communication, and risk assessment.

- New skin corrosion/irritation classification. The new revision now includes detailed instructions on how to use in vitro/ex vivo test data to analyze whether a substance or mixture causes skin irritation and corrosion.

GHS Labeling Requirements

OSHA’s GHS labeling requirements are now an extension of their Hazard Communication Program requirements since they have been aligned to promote continuity between SDSs and other companies labeling efforts. These requirements consist of four primary parts:

- The signal word

- GHS pictogram(s)

- The hazard statement

- The precautionary statement

Aside from these four components, which are explained in the following sections, the label must also include the product identifier and the supplier’s information.

Signal words help people immediately gauge the level of risk associated with a hazardous chemical in a labeled container. There are two approved GHS signal words that are used today, however, only one signal word should be used per label:

- “Danger” should be used when the hazardous chemical being labeled can cause an immediate serious risk such as death or chronic health problems.

- “Warning” should be used when the hazardous chemical requires a prolonged exposure to result in health issues.

There are nine pictograms that have been officially approved by GHS. Most companies today will employ all nine of these pictograms in their GHS labeling strategies .

- Health Hazard – Use for chemicals that can cause cancer, mutations, reproductive issues, developmental issues, etc.

- Flame – Use for flammable solids, liquids or gasses.

- Exclamation Mark – Use for chemicals that can cause damage to skin, eyes, or result in other mild irritations.

- Gas Cylinder – Use for any gasses that are contained under pressure.

- Corrosion – Use for chemicals that cause burns or damage metal due to its corrosive properties.

- Exploding Bomb – Use for any substance or mixture that can cause an explosion, whether it needs an ignitor to explode or not.

- Flame over Circle – Use for oxidizing chemicals.

- Environment - Use for aquatic toxins that harm fish, water-based animals, plants, and other life.

- Skull & Crossbones – Use for poisons, whether the poison can cause harm via eating, skin exposure, inhalation or any other method.

The proper use of GHS hazard statements is not only important for remaining in compliance with OSHA requirements, but also for keeping everyone safe. The following are categories of codes that can be used in a hazard statement . Each of the three categories have multiple specific codes within that must be chosen based on the chemical’s properties:

- Physical Hazards – Use for chemical hazards that cause a physical hazard such as a fire, explosion, or other issues.

- H200-H208: Unstable Explosives

- H221-H228: Flammable Gas/Vapor/Liquid/Solid

- H230-H232: Sensitive to Air Exposure

- H240-H252: Heating May Cause Fire

- H260-H261: Unstable in the Prescence of Water

- H270 - H272:Oxidizer

- H280 - H281: Gas Containment Issues

- H290: Corrosive to Metals

- Health Hazards – Use for chemical hazards that cause a health problem when consumed, inhaled, exposed to skin, or in other situations.

- H300-H305: Harmful if Swallowed

- H310-H320: Causes skin and eye issues

- H330-H336: Harmful if Inhaled

- H340 - H341: Genetic Defects

- H350-H351: May Cause Cancer

- H360-H362: Fertility

- H370 - H373: Organ Damage

- Environmental Hazards – Use for chemical hazards that cause negative aquatic environmental issues.

- H400-H401: Toxic to Aquatic Life

- H402: Harmful to Aquatic Life

- H410-H413: Toxic/Harmful to Aquatic Life with Long-Lasting Effects

- H420: Ozone Destruction

- H433: Harmful to Terrestrial Vertebrates

Precautionary statements provide readers with information regarding what steps need to be taken in the event of an exposure and to minimize exposure of hazardous chemicals. There are five different types of precautionary statements that can be used on a GHS label and within SDSs, they and their “P” code formats are as follows:

- General – Code P1xx, example “Read label before use”

- Prevention – Code P2xx, example “Obtain special instruction before use”

- Response – Code P3xx, example “IF SWALLOWED:”

- Storage – Code P4xx, example “Store locked up”

- Disposal – Code P5xx, example “Dispose of contents/container to…”

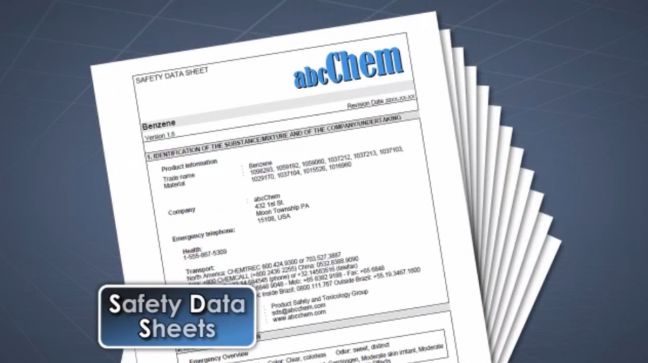

Safety data sheets, also known as SDSs, are used to communicate specific hazards related to chemical products. Similar to the Globally Harmonized System labeling requirements, there are a variety of specific standards to follow for all safety data sheets.

There are multiple sections that should be used when creating a safety data sheet. The following are the 16 sections that must be included:

- Identification

- Hazard Information

- Composition of Ingredients

- First Aid Information

- Fire Fighting Information

- Accidental Release Information

- Handling and Storage Information

- Exposure Control Information

- Physical and Chemical Properties

- Stability and Reactivity Information

- Toxicological Information

- Ecological Information

- Disposal Information

- Transport Information

- Regulatory Information

- Other Information

GHS Compliance

The first thing to note when it comes to GHS compliance is that it’s not an international law. Many people hear that it was developed by the United Nations and think that there may be some sort of UN enforcement, but that is not the case. The UN largely created the standards and made them available to people and governments around the world. They do not, however, have any requirements or enforcement power related to whether or not any country or company follows their standards.

The simple reason why GHS is followed is because it is considered to be the best practice method for labeling hazardous chemicals. OSHA and other standard setting bodies encourage companies to follow these GHS standards to help keep their employees as safe as possible.

- The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) is a system that provides standardized criteria for classifying and communicating chemical hazards on labels and safety data sheets. It was adopted by the United Nations in 2002 and is now implemented in many countries around the world. Source: https://en.wikipedia.org/wiki/Globally_Harmonized_System_of_Classification_and_Labelling_of_Chemicals

- The GHS labels include four elements: a signal word (either “danger” or “warning”), a pictogram (a symbol that conveys the type of hazard), a hazard statement (a phrase that describes the nature and degree of the hazard), and a precautionary statement (a phrase that gives advice on how to prevent or minimize the adverse effects of the hazard). Source: https://www.epa.gov/sites/default/files/2017-04/documents/session-4f-ghs-fact-sheet.pdf

- In 2012, OSHA revised its Hazard Communication Standard (HCS) to align with the GHS. This update required chemical manufacturers and importers to reclassify their chemicals and update their labels and safety data sheets by June 1, 2015. Employers were also required to train their workers on the new label elements and safety data sheet format by December 1, 2013. Source: https://www.osha.gov/hazcom/global

- The benefits of aligning the HCS with the GHS include improved protection of workers and the environment, enhanced consistency and quality of information, reduced trade barriers and costs, and increased productivity and efficiency. Source: https://usbioclean.com/hcs-ghs-frequently-asked-questions/

- The GHS is not a static system, but a dynamic one that is regularly updated and revised to reflect new scientific data and best practices. The most recent revision of the GHS is the ninth edition, published in 2020. Source: https://unece.org/about-ghs

Similar Articles

- GHS Label Creation

- GHS Label Information

- Understanding the NFPA 704 Diamond Labeling System

- Material Safety Data Sheets [How-To Guide for Upgrading to SDS]

- Hazardous Materials Identification System (HMIS Labels)

- Your Guide to Pipe Labeling Standards

- Hazard Pictograms

- Solar System Labeling

- Waste Water Treatment Labeling

Free E-Book

A step-by-step guide to GHS compliance.

Download now ›

Learn how simple organizational strategy can transform your business.

Guide to OSHA Safety Signs

- What does GHS stand for?

- GHS Labeling

- What is HazCom?

Helpful Resources

Oops, something went wrong. Please try again.

You are now logged in!

- Skip to main content

- Skip to site information

- Departments

Language selection

- Français

Scheduled maintenance - Thursday, July 12 at 5:00 PM EDT

We expect this update to take about an hour. Access to this website will be unavailable during this time.

Globally Harmonized System (GHS)

On this page, what is the globally harmonized system (ghs), why was ghs developed, what is the scope of ghs, what are some key terms in the ghs vocabulary, how is ghs organized , what are the classes within the health hazard group, what are the classes within the physical hazard group, what are the classes within the environmental hazard group, where can i get information on the ghs criteria for the different hazard classes, is the adoption of ghs mandatory for all countries around the globe/world, how is ghs adopted by a country, when a country decides to adopt ghs, must all ghs elements be adopted, who enforces ghs , where can i get more information.

GHS stands for the Globally Harmonized System of Classification and Labelling of Chemicals.

It is a system of hazard communication for chemical hazards that can be adopted by countries around the world. GHS was developed by a United Nations (UN) international team of hazard communication experts. They established the following two major standardized elements:

1. rules for classifying the hazards of chemical products (i.e., substances, materials, or mixtures)

- format for safety data sheets (SDSs),

- content for label and SDSs with

- hazard and precautionary statements

- signal word

GHS was developed because many different countries had different systems for classification and labelling of chemical products. In addition, several different systems can exist even within the same country.

While existing systems were similar in many respects, their differences were significant enough to result in different hazard classifications, labels, or SDS for the same product. For example, one country may classify a product as carcinogenic while another country will not.

This situation has been expensive for governments to regulate and enforce, costly for companies who have to comply with many different systems, and confusing for workers who need to understand the hazards of a chemical in order to work safely.

As more and more countries adopt the principles of GHS, the benefits include:

- Promoting regulatory efficiency.

- Facilitating trade.

- Easing compliance.

- Reducing costs.

- Providing improved, consistent hazard information.

- Encouraging the safe transport, handling and use of chemicals.

- Promoting better emergency response to chemical incidents.

- Reducing the need for animal testing.

GHS covers all hazardous chemicals products, such as those used for the following purposes:

- industrial chemicals

- consumer chemical products

- agricultural chemicals

- pharmaceuticals

- SDS – Safety Data Sheet. The GHS SDS has 16 sections in a set order, and minimum information is prescribed.

- Labels - With the GHS, certain information will appear on the label. Standardized elements such as chemical identify, hazard statements, signal words and symbols will appear on the label according to the classification of that chemical or mixture. Precautionary statements may also be required, if adopted by your regulatory authority.

- Hazard group – While not given a formal definition, GHS divides hazards into three major groups – health, physical and environmental.

- Class – Class is the term used to describe the different types of hazards. For example, Gases under Pressure is an example of a class in the physical hazards group.

- Category – Category is the name used to describe the sub-sections of classes. For example, Self-Reactive Chemicals have 7 categories. Each category has rules or criteria to determine what chemicals are assigned to that category. Categories are assigned numbers (or letters) with category 1 (or A) being the most hazardous.

- Hazard Statement – For each category of a class, a standardized statement is used to describe the hazard. For example, the hazard statement for chemicals which meet the criteria for the class Self-heating substances and mixtures, Category 1 is Self-heating; may catch fire. This hazard statement would appear both on the label and on the SDS.

- Precautionary Statement – These statements are standardized phrases that describe the recommended steps to be taken to minimize or prevent adverse effects from exposure to or resulting from improper handling or storage of a hazardous product.

- Signal word – There are two signal words used by the GHS – Danger and Warning. These signal words are used to communicate the level of hazard on both the label and the SDS. The appropriate signal word to use is set out by the classification system. For example, the signal word for Self-heating substances and mixtures, Category 1 is Danger while Warning is used for the less serious Category 2. There are categories where no signal word is used.

- Pictogram – Pictogram refers to the GHS symbol on the label and SDS. Not all categories have a pictogram associated with them.

GHS consists of three major hazard groups :

- Physical hazards.

- Health hazards.

- Environmental hazards.

Within each of these hazard groups there are classes and categories.

Criteria for classifying chemicals have been developed for the following health hazard classes:

- Acute toxicity.

- Skin corrosion/irritation.

- Serious eye damage/eye irritation.

- Respiratory or skin sensitization.

- Germ cell mutagenicity.

- Carcinogenicity.

- Reproductive toxicity.

- Specific target organ toxicity - single exposure.

- Specific target organ toxicity - repeated exposure.

- Aspiration hazard.

Criteria for classifying chemicals have been developed for the following physical hazard classes:

- Explosives.

- Flammable gases.

- Oxidizing gases.

- Gases under pressure.

- Flammable liquids.

- Flammable solids.

- Self-reactive substances and mixtures.

- Pyrophoric liquids.

- Pyrophoric solids.

- Self-heating substances and mixtures.

- Substances and mixtures which, in contact with water, emit flammable gases.

- Oxidizing liquids.

- Oxidizing solids.

- Organic peroxides.

- Corrosive to metals.

Criteria for classifying chemicals have been developed for the following environmental hazard classes:

- Hazardous to the aquatic environment (acute and chronic).

- Hazardous to the ozone layer.

The GHS criteria are specified in the publication known as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS ) from the United Nations Economic Commission for Europe (UNECE) (this publication is often referred to as the “purple book”.) The first edition of this book was published in 2003. Since then, the GHS book has been revised every two years as needed and as experience is gained in its implementation. All editions are available in multiple languages and can be accessed for free at the UNECE website .

When checking the criteria for a particular hazard class and or a category, make sure that you are viewing the revised edition of the GHS purple book that corresponds to the version that was adopted by your country.

No. The GHS is a 'non-binding' system of hazard communication. However, as mentioned above, there are many benefits when it is voluntarily adopted by countries around the globe.

It is up to the country’s authorities to decide how GHS will be adopted in their legislation. For example, Canada adopted the GHS by revising the existing WHMIS legislation.

No. When a country adopts GHS, the country has freedom to:

- Select one or more of the hazard classes

- Select the categories it will adopt for a particular hazard class

The key is that when a GHS hazard class is adopted by a country, the country must adopt that hazard class as specified by GHS. This adoption will help make sure that each country has the same classification criteria as each other. For example, if a country adopts the flammable hazard class and only the Category 1 level, the criteria for Category 1 will be the same for all the countries that adopted this Category.

In situations where the country had regulations concerning hazard classes that are not included in GHS, the country is free to include or create legislation to maintain desired levels of protection.

The UNECE publishes information about the status of implementation of GHS by country . Examples include:

Canada adopted GHS in February 2015 by amending the federal Hazardous Product Act (HPA) and the publication of a new regulation titled Hazardous Products Regulations (HPR) under the HPA which is commonly referred to as the federal Workplace Hazardous Materials Information System 2015 (WHMIS 2015) legislation. Provincial and territorial jurisdictions also updated their related legislation. Note that the amendment of the HPA and implementation of the new HPR is based on the fifth revised edition (Rev 5). Amendments are expected from time to time to keep WHMIS in alignment with current GHS recommendations. WHMIS 2015 regulatory updates can be monitored by checking:

- Canada’s National WHMIS Portal ( www.whmis.org )

- WHMIS News – Workplace Hazardous Materials Information System – Health Canada

- Forward Regulatory Plan 2021-2023: Regulations Amending the Hazardous Products Regulations (GHS, Seventh Revised Edition) and Order Amending Schedule 2 to the Hazardous Products Act

United States (USA)

United States adopted the GHS elements from the 3rd revised edition of the GHS purple book in their Hazardous Communication Standard (HCS) in 2012. This standard is commonly referred to as HCS 2012 and is currently in full force. OSHA is conducting rulemaking to harmonize the HCS to the latest edition of the GHS and to codify a number of enforcement policies that have been issued since the 2012 standard. In their “OSHA Trade Release”, OSHA announced that they are issuing a proposed rule to update the HCS 2012 with the 7th revised edition of the GHS purple book. Check regulatory updates at:

- OSHA Trade Release https://www.osha.gov/news/newsreleases/trade/02052021

Information and resources for the current US HCS 2012 standard is available at:

- Hazard communication https://www.osha.gov/hazcom

GHS implementation: EU and European Economic Area

https://unece.org/transport/documents/2021/01/ghs-implementation-eu-and-european-economic-area

Other Countries

Information on the status of GHS implementation in other countries is available at the UNECE website: GHS implementation: Implementation by country https://unece.org/transport/documents/2021/01/ghs-implementation-implementation-country

There is no global organization (e.g., UN, WHO, etc.) that enforces GHS for different countries. Once a country adopts GHS elements (e.g., hazard classes) in its own legislation (e.g., WHMIS), they are enforced by the country’s own authorities.

For example, in Canada when a supplier’s WHMIS label or SDS are incorrect, Health Canada will enforce the federal WHMIS legislation. Meanwhile, provincial or territorial health and safety authorities enforce their jurisdiction’s WHMIS legislation.

Information from across Canada is available on the website WHMIS.org .

Health Canada also offers an email news service to announce information about WHMIS.

- Fact sheet last revised: 2021-08-25

GHS Hazard Statement List

GHS hazard statement means a standard phrase assigned to a hazard class and category to describe the nature and severity of a chemical hazard. Each hazard statement is designated a code, starting with the letter H and followed by 3 digits.

- H2xx : Physical hazards;

- H3xx : Health hazards;

- H4xx : Environmental hazards.

It shall be noted that the H code is used for reference purpose only. It is the actual phrase which should appear on labels and safety data sheets.

Note : If you wish to quickly search a hazard statement and signal word based on GHS hazard classification and H code, please go to our free hazard statement and signal word finder.

- Hazard statement and signal word finder

List of GHS Hazard Statements and H Codes

H200: Unstable explosive

H201: Explosive; mass explosion hazard

H202: Explosive; severe projection hazard

H203: Explosive; fire, blast or projection hazard

H204: Fire or projection hazard

H205: May mass explode in fire

H206: Fire, blast or projection hazard; increased risk of explosion if desensitizing agent is reduced

H207: Fire or projection hazard; increased risk of explosion if desensitizing agent is reduced

H208: Fire hazard; increased risk of explosion if desensitizing agent is reduced

H220: Extremely flammable gas

H221: Flammable gas

H222: Extremely flammable aerosol

H223: Flammable aerosol

H224: Extremely flammable liquid and vapour

H225: Highly flammable liquid and vapour

H226: Flammable liquid and vapour

H227: Combustible liquid

H228: Flammable solid

H229: Pressurized container: may burst if heated

H230: May react explosively even in the absence of air

H231: May react explosively even in the absence of air at elevated pressure and/or temperature

H232: May ignite spontaneously if exposed to air

H240: Heating may cause an explosion

H241: Heating may cause a fire or explosion

H242: Heating may cause a fire

H250: Catches fire spontaneously if exposed to air

H251: Self-heating; may catch fire

H252: Self-heating in large quantities; may catch fire

H260: In contact with water releases flammable gases which may ignite spontaneously

H261: In contact with water releases flammable gas

H270: May cause or intensify fire; oxidizer

H271: May cause fire or explosion; strong oxidizer

H272: May intensify fire; oxidizer

H280: Contains gas under pressure; may explode if heated

H281: Contains refrigerated gas; may cause cryogenic burns or injury

H290: May be corrosive to metals

H300: Fatal if swallowed

H301: Toxic if swallowed

H302: Harmful if swallowed

H303: May be harmful if swallowed

H304: May be fatal if swallowed and enters airways

H305: May be harmful if swallowed and enters airways

H310: Fatal in contact with skin

H311: Toxic in contact with skin

H312: Harmful in contact with skin

H313: May be harmful in contact with skin

H314: Causes severe skin burns and eye damage

H315: Causes skin irritation

H316: Causes mild skin irritation

H317: May cause an allergic skin reaction

H318: Causes serious eye damage

H319: Causes serious eye irritation

H320: Causes eye irritation

H330: Fatal if inhaled

H331: Toxic if inhaled

H332: Harmful if inhaled

H333: May be harmful if inhaled

H334: May cause allergy or asthma symptoms or breathing difficulties if inhaled

H335: May cause respiratory irritation

H336: May cause drowsiness or dizziness

H340: May cause genetic defects

H341: Suspected of causing genetic defects

H350: May cause cancer

H351: Suspected of causing cancer

H360: May damage fertility or the unborn child

H361: Suspected of damaging fertility or the unborn child

H361d: Suspected of damaging the unborn child

H362: May cause harm to breast-fed children

H370: Causes damage to organs

H371: May cause damage to organs

H372: Causes damage to organs through prolonged or repeated exposure

H373: May cause damage to organs through prolonged or repeated exposure

H400: Very toxic to aquatic life

H401: Toxic to aquatic life

H402: Harmful to aquatic life

H410: Very toxic to aquatic life with long-lasting effects

H411: Toxic to aquatic life with long-lasting effects

H412: Harmful to aquatic life with long-lasting effects

H413: May cause long-lasting harmful effects to aquatic life

H420: Harms public health and the environment by destroying ozone in the upper atmosphere

How to Determine GHS Hazard Statements for A Chemical?

You have to determine the hazard class and hazard category of a chemical first. Once the classification of a chemical has been determined, signal word, hazard pictograms, hazard statements and precautionary statements will be assigned (see example below for flammable liquids).

EU Supplementary Hazard Statements List

It shall be noted that EU CLP regulation has kept many additional hazard statements which cannot be found in GHS. Those hazard statements can be found below:

EUH001: Explosive when dry.

EUH006: Explosive with or without contact with air.

EUH014: Reacts violently with water.

EUH018: In use, may form flammable/explosive vapour-air mixture.

EUH019: May form explosive peroxides.

EUH044: Risk of explosion if heated under confinement.

EUH029: Contact with water liberates toxic gas.

EUH031: Contact with acids liberates toxic gas.

EUH032: Contact with acids liberates very toxic gas.

EUH066: Repeated exposure may cause skin dryness or cracking.

EUH070: Toxic by eye contact.

EUH071: Corrosive to the respiratory tract.

EUH059: Hazardous to the ozone layer.

EUH201: Contains lead. Should not be used on surfaces liable to be chewed or sucked by children.

EUH201A: Warning! Contains lead.

EUH202: Cyanoacrylate. Danger. Bonds skin and eyes in seconds. Keep out of the reach of children.

EUH203: Contains chromium (VI). May produce an allergic reaction.

EUH204: Contains isocyanates. May produce an allergic reaction.

EUH205: Contains epoxy constituents. May produce an allergic reaction.

EUH206: Warning! Do not use together with other products. May release dangerous gases (chlorine)

EUH207: Warning! Contains cadmium. Dangerous fumes are formed during use. See information supplied by the manufacturer. Comply with the safety instructions.

EUH208: Contains (name of sensitising substance). May produce an allergic reaction.

EUH209: Can become highly flammable in use.

EUH209A: Can become flammable in use.

EUH210: Safety data sheet available on request.

EUH401: To avoid risks to human health and the environment, comply with the instructions for use.

Hazard Statements List - EU Translations

Click here to download hazard statements list in various EU languages.

Advanced GHS Topics

- Global GHS Implementation

- GHS Precedence Rules for Pictogram, Signal Word and Hazard Statement

- GHS Classification of Mixture

- GHS Bridging Principles

- GHS Cut-off value/concentration Limit

- Global GHS Label Size Requirement

- Global GHS Label Requirement for Small Containers

- GHS and Pesticides

- GHS Classification List

- GHS and Confidential Business Info

- Comparing GHS Builing Blocks in EU, USA, China and Japan

- Correlations between TDG and GHS

- When Shou You Update Your SDSs

Having Questions?

We do not provide consultancy services. If you have questions or need any help, please contact our sponsor. You may also find an expert in CSP business directory below. If you are a consultant, you may get yourself listed in CSP business directory (free) or sponsor this page to leave your contact info on this page..

Tags: Topics - GHS , GHS Basics and Tutorials

What Is New?

Subscribe to Free Newsletter View Past Newsletter

Recommended for You

- Top News of the Month

- EU Chemical Strategy for Sustainability

- Chemicals in Electronics

- PFAS Regulation

- Biocides and Biocidal Product Regulations

- Cosmetics and Personal Care

- Food Contact Materials

- Reports and Guides

- Events and Training

Hot Articles

- Slovenščina

Useful informations

Customer service, hazard statements.

Safety data sheet knowledge base – Hazard statements

Hazard and Precautionary statements are codified using a unique alphanumerical code which consists of one letter and three numbers, as follows:

- the letter “H” (for “hazard statement”) or “P” (for “precautionary statement”). Please note that hazard statements carried through from DSD and DPD, but which are not included in the GHS are codified as “EUH”;

- a digit designating the type of hazard, e.g. ”2” for physical hazards; and

- two numbers corresponding to the sequential numbering of hazards such as explosivity (codes from 200 to 210), flammability (codes from 220 to 230), etc.

Your labels must also bear the relevant hazard statements describing the nature and severity of the hazards of your substance or mixture (CLP Article 21).

The hazard statements relevant for each specific hazard classification are set out in the tables contained in parts 2 to 5 of Annex I to CLP. If a substance classification is harmonised and included in Part 3 of Annex VI to CLP, the corresponding hazard statement relevant for this classification must be used on the label, together with any other hazard statement for a non-harmonised classification.

Annex III to CLP lists the correct wording of the hazard statements as they should appear on the labels. The hazard statements of one language must be grouped together with the precautionary statements of the same language on the label .

The revised list of hazard statements contains the new or modified statements, highlighted in red, that, according to the Commission Regulation (EU) No 2019/521, are applicable from 17 October 2020.

EN I DE I FR I ES I IT I PL I CS I RO I SL I SK I HU

Downloading the list of applicable hazard statements. In force from 17 October 2020.

In force from 17 October 2020

H200 – Unstable explosives.

H201 – Explosive; mass explosion hazard.

H202 – Explosive, severe projection hazard.

H203 – Explosive; fire, blast or projection hazard.

H204 – Fire or projection hazard.

H205 – May mass explode in fire.

H206 – Fire, blast or projection hazard; increased risk of explosion if desensitising agent is reduced.

H207 – Fire or projection hazard; increased risk of explosion if desensitising agent is reduced.

H208 – Fire hazard; increased risk of explosion if desensitising agent is reduced.

H220 – Extremely flammable gas.

H221 – Flammable gas.

H222 – Extremely flammable aerosol.

H223 – Flammable aerosol.

H224 – Extremely flammable liquid and vapour.

H225 – Highly flammable liquid and vapour.

H226 – Flammable liquid and vapour.

H228 – Flammable solid.

H229 – Pressurised container: May burst if heated.

H230 – May react explosively even in the absence of air.

H231 – May react explosively even in the absence of air at elevated pressure and/or temperature.

H232 – May ignite spontaneously if exposed to air.

H240 – Heating may cause an explosion.

H241 – Heating may cause a fire or explosion.

H242 – Heating may cause a fire.

H250 – Catches fire spontaneously if exposed to air.

H251 – Self-heating: may catch fire.

H252 – Self-heating in large quantities; may catch fire.

H260 – In contact with water releases flammable gases which may ignite spontaneously.

H261 – In contact with water releases flammable gases.

H270 – May cause or intensify fire; oxidiser.

H271 – May cause fire or explosion; strong oxidiser.

H272 – May intensify fire; oxidiser.

H280 – Contains gas under pressure; may explode if heated.

H281 – Contains refrigerated gas; may cause cryogenic burns or injury.

H290 – May be corrosive to metals.

H300 – Fatal if swallowed.

H301 – Toxic if swallowed.

H302 – Harmful if swallowed.

H304 – May be fatal if swallowed and enters airways.

H310 – Fatal in contact with skin.

H311 – Toxic in contact with skin.

H312 – Harmful in contact with skin.

H314 – Causes severe skin burns and eye damage.

H315 – Causes skin irritation.

H317 – May cause an allergic skin reaction.

H318 – Causes serious eye damage.

H319 – Causes serious eye irritation.

H330 – Fatal if inhaled.

H331 – Toxic if inhaled.

H332 – Harmful if inhaled.

H334 – May cause allergy or asthma symptoms or breathing difficulties if inhaled.

H335 – May cause respiratory irritation.

H336 – May cause drowsiness or dizziness.

H340 – May cause genetic defects <state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard >.

H341 – Suspected of causing genetic defects <state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard>.

H350 – May cause cancer <state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard>.

H350i – May cause cancer by inhalation.

H351 – Suspected of causing cancer <state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard>.

H360 – May damage fertility or the unborn child <state specific effect if known > <state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard>.

H360F – May damage fertility.

H360D – May damage the unborn child.

H360FD – May damage fertility. May damage the unborn child.

H360Fd – May damage fertility. Suspected of damaging the unborn child.

H360Df – May damage the unborn child. Suspected of damaging fertility.

H361 – Suspected of damaging fertility or the unborn child <state specific effect if known> <state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard>.

H361f – Suspected of damaging fertility.

H361d – Suspected of damaging the unborn child.

H361fd – Suspected of damaging fertility. Suspected of damaging the unborn child.

H362 – May cause harm to breast-fed children.

H370 – Causes damage to organs <or state all organs affected, if known> <state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard>.

H371 – May cause damage to organs <or state all organs affected, if known> <state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard>.

H372 – Causes damage to organs <or state all organs affected, if known> through prolonged or repeated exposure <state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard>.

H373 – May cause damage to organs <or state all organs affected, if known> through prolonged or repeated exposure <state route of exposure if it is conclusively proven that no other routes of exposure cause the hazard>.

H300 + H310 – Fatal if swallowed or in contact with skin.

H300 + H330 – Fatal if swallowed or if inhaled.

H310 + H330 – Fatal in contact with skin or if inhaled.

H300 + H310 + H330 – Fatal if swallowed, in contact with skin or if inhaled.

H301 + H311 – Toxic if swallowed or in contact with skin.

H301 + H331 – Toxic if swallowed or if inhaled.

H311 + H331 – Toxic in contact with skin or if inhaled.

H301 + H311 + H331 – Toxic if swallowed, in contact with skin or if inhaled.

H302 + H312 – Harmful if swallowed or in contact with skin.

H302 + H332 – Harmful if swallowed or if inhaled.

H312 + H332 – Harmful in contact with skin or if inhaled.

H302 + H312 + H332 – Harmful if swallowed, in contact with skin or if inhaled.

H400 – Very toxic to aquatic life.

H410 – Very toxic to aquatic life with long lasting effects.

H411 – Toxic to aquatic life with long lasting effects.

H412 – Harmful to aquatic life with long lasting effects.

H413 – May cause long lasting harmful effects to aquatic life.

H420 – Harms public health and the environment by destroying ozone in the upper atmosphere.

EUH 014 – Reacts violently with water.

EUH 018 – In use may form flammable/explosive vapour- air mixture.

EUH 019 – May form explosive peroxides.

EUH 044 – Risk of explosion if heated under confinement.

EUH 029 – Contact with water liberates toxic gas.

EUH 031 – Contact with acids liberates toxic gas.

EUH 032 – Contact with acids liberates very toxic gas.

EUH 066 – Repeated exposure may cause skin dryness or cracking.

EUH 070 – Toxic by eye contact.

EUH 071 – Corrosive to the respiratory tract.

EUH 201/ 201A – Contains lead. Should not be used on surfaces liable to be chewed or sucked by children. Warning! Contains lead.

EUH 202 – Cyanoacrylate. Danger. Bonds skin and eyes in seconds. Keep out of the reach of children.

EUH 203 – Contains chromium (VI). May produce an allergic reaction.

EUH 204 – Contains isocyanates. May produce an allergic reaction.

EUH 205 – Contains epoxy constituents. May produce an allergic reaction.

EUH 206 – Warning! Do not use together with other products. May release dangerous gases (chlorine).

EUH 207 – Warning! Contains cadmium. Dangerous fumes are formed during use. See information supplied by the manufacturer. Comply with the safety instructions.

EUH 208 – Contains <name of sensitising substance>. May produce an allergic reaction.

EUH 209/ 209A – Can become highly flammable in use. Can become flammable in use.

EUH 210 – Safety data sheet available on request.

EUH 211 – Warning! Hazardous respirable droplets may be formed when sprayed. Do not breathe spray or mist.

EUH 212 – Warning! Hazardous respirable dust may be formed when used. Do not breathe dust

EUH 401 – To avoid risks to human health and the environment, comply with the instructions for use.

Downloading the list of applicable hazard statements

Offered services

- Translation of safety data sheet

- Revision, update of safety data sheets

- Compilation, creation of a safety data sheet

- Safety data sheet express services within 24 hours

- Compilation of label

Recommended article(s)

- Label elements of the safety data sheet

- CLP labelling in practice

- Hazard pictogram

- P statements

Tags: CLP labelling , safety data sheet , safety data sheet knowledge base

Hazard and Precautionary Statements

Hazard statements, precautionary statements, pictograms and hazard codes.

There are 72 individual and 17 combined Hazard statements - these are assigned a unique alphanumerical code which consists of one letter and three numbers as follows:

- the letter "H" (for "hazard statement");

- "2" for physical hazards

- "3" for health hazards

- "4" for environmental hazards

- two numbers corresponding to the sequential numbering of hazards arising from the intrinsic properties of the substance or mixture, such as explosive properties (codes from 200 to 210), flammability (codes from 220 to 230), etc.

Hazard Statement Chart

There are 116 individual and 33 combined Precautionary statements – these are assigned a unique alphanumerical code which consists of one letter and three numbers as follows:

- the letter "P" (for "precautionary statement");

- "1" for general precautionary statements

- "2" for prevention precautionary statements

- "3" for response precautionary statements

- "4" for storage precautionary statements

- "5" for disposal precautionary statements

- two numbers (corresponding to the sequential numbering of precautionary statements)

Precautionary Statement Chart

Compared to the current EU system the most noticeable change are the pictograms (formerly: hazard symbols). While the most of the GHS pictograms have an equivalent in the old system, the pictograms GHS 04, GHS 07 and GHS 08 are completely new.

The GHS System is built on 16 physical, 10 health and 3 environmental hazard classes and comprises the following communication elements:

9 Pictograms Chart

To continue reading please sign in or create an account.

Research. Development. Production.

We are a leading supplier to the global Life Science industry with solutions and services for research, biotechnology development and production, and pharmaceutical drug therapy development and production.

© 2024 Merck KGaA, Darmstadt, Germany and/or its affiliates. All Rights Reserved.

Reproduction of any materials from the site is strictly forbidden without permission.

- English - EN

- Español - ES

Solutions for

Educator & Staff Training

Improve compliance and deliver critical professional development with online courses and management system

Safety & Compliance

Inclusive Instruction & Interventions

Diversity & Inclusion

School Bus Driver

Cybersecurity Awareness

Facilities Maintenance

Child Sexual Abuse Prevention

Student Safety & Wellness Program NEW

Student Safety & Wellness Program

Keep students safe and healthy with safety, well-being, and social and emotional learning courses and lessons

Substance Misuse Prevention Courses

Mental Health & Well-Being Courses

Healthy Relationships Courses

Personal & Community Safety Courses

Career Readiness & Life Skills NEW

Professional Growth Management

Integrated software to manage and track evaluations and professional development and deliver online training

Professional Development Management

Evaluations Management

Anonymous Reporting & Safety Communications

Empower your school community to ask for help to improve school safety and prevent crises before they occur

Incident & EHS Management

Streamline safety incident reporting and management to improve safety, reduce risk, and increase compliance

Higher Education

Student Training

Increase safety, well-being, and belonging with proven-effective training on critical prevention topics

Sexual Assault Prevention

Alcohol & Drug Misuse Prevention

Diversity, Inclusion, & Belonging

Wellness & Safety

Career & Personal Development NEW

Fraternity & Sorority Life

Faculty & Staff Training

Create a safe, healthy, and welcoming campus environment and improve compliance with online training courses

Harassment, Discrimination, & Sexual Assault Prevention

IT & Campus Security

Health & Safety

Human Resources & Workforce Management

Environmental Health & Facilities Management

Campus Climate Surveys

Simplify VAWA compliance with easy, scalable survey deployment, tracking, and reporting

Empower your faculty, staff, and students to take an active role in protecting themselves and others

Manufacturing

Safety Training NEW

Safety Training

Elevate performance and productivity while reducing risk across your entire organization with online training.

MSHA Training

Industrial Skills Training NEW

Industrial Skills Training

Close skills gap, maximize production, and drive consistency with online training

Core Industrial Skills

Preventative Maintenance

Electrical Maintenance

Continuous Improvement

Power Generation

Paper Manufacturing Training

Enhance worker expertise and problem-solving skills while ensuring optimal production efficiency.

HR & Compliance

Provide role-specific knowledge, develop skills, and improve employee retention with career development training.

Professional Development NEW

DEI Training NEW

Anti Harassment Training NEW

Learning Management System (LMS)

Assign, track, and report role-based skills and compliance training for the entire workforce

Competency Assessments NEW

EHS Management

Track, Analyze, Report Health and Safety Activities and Data for the Industrial Workforce

Incident Management

Inspections & Audits

Real-TIme Safety Metrics and Reports

Behavior-Based Safety

Hazard Reporting

Job Safety Analysis

SDS & Chemical Management

Safety Communication

Enhance the safety for the industrial workforce with two-way risk communications, tools, and resources

Fire Departments

Training Management

A training management system tailored for the fire service--track all training, EMS recerts, skill evaluations, ISO, and more in one place

Training Management System

Skill Evaluations

Firefighter Continuing Education

Online EMS Recertification Training

Fire Academy Automation

Fire Standards and Training

Crew Shift Scheduling

Simplify 24/7 staffing and give firefighters the convenience of accepting callbacks and shifts from a mobile device

Checks & Inventory Management

Streamline truck checks, PPE inspections, controlled substance tracking, and equipment maintenance with a convenient mobile app

Controlled Substance Tracking

Exposure and Critical Incident Monitoring NEW

Exposure and Critical Incident Monitoring

Document exposures and critical incidents and protect your personnels’ mental and physical wellness

Training Management and Recertification

A training management system tailored for EMS services—EMS online courses for recerts, mobile-enabled skill evaluations, and more

EMS Skill Evaluations

EMS Shift Scheduling

Simplify 24/7 staffing and give medics the convenience of managing their schedules from a mobile device

Inventory Management

Streamline vehicle checks, controlled substance tracking, and equipment maintenance with a convenient mobile app

Wellness Monitoring & Exposure Tracking NEW

Wellness Monitoring & Exposure Tracking

Law Enforcement

Training and FTO Management

Increase performance, reduce risk, and ensure compliance with a training management system tailored for your FTO/PTO and in-service training

Training Management System & FTO

Law Enforcement Online Training

Academy Automation

POST and Regulatory Management

Early Intervention & Performance Management

Equip leaders with a tool for performance management and early intervention that helps build positive agency culture

Officer Shift Scheduling

Simplify 24/7 staffing and give officers the convenience of managing their schedules from a mobile device

Asset Mangagement & Inspections

Streamline equipment checks and vehicle maintenance to ensure everything is working correctly and serviced regularly

Energy Skills Training

Empower your team with skills and safety training to ensure compliance and continuous advancement.

Track, analyze, report health and safety activities and data for the industrial workforce

Lone Worker Safety

Enhance lone worker safety with two way risk communications, tools, and resources

Federal Training Management

Lower training costs and increase readiness with a unified system designed for high-risk, complex training and compliance operations.

Military Training Management

Increase mission-readiness and operational efficiency with a unified system that optimizes military training and certification operations.

Local Government Training Management

Technology to train, prepare, and retain your people

Fire Marshall Training & Compliance

Improve fire service certification and renewal operations to ensure compliance and a get a comprehensive single source of truth.

Elevate fire academy training with automation software, enhancing efficiency and compliance.

POST Training & Compliance

Streamline your training and standards operations to ensure compliance and put an end to siloed data.

Law Enforcement Academy Automation

Modernize law enforcement training with automation software that optimizing processes and centralizes academy information in one system.

Simplify incident reporting to OSHA and reduce risk with detailed investigation management.

Architecture, Engineering & Construction

Ensure licensed professionals receive compliance and CE training via online courses and learning management.

Online Continuing Education

Keep AEC staff licensed in all 50 states for 100+ certifications with online training

Architecture

Engineering

Construction

Project Management

Drive organizational success with training that grows skills and aligns with the latest codes and standards

Heath & Safety

Construction and Trades

Track, Analyze, Report Health and Safety Activities and Data for AEC Worksites

Inspections and Audits

Real-Time Safety Metrics and Reports

Enhance AEC workforce safety with two-way risk communications, tools, and resources

Anti-Money Laundering Training

Reduce risk in casino operations with Title 31 and Anti-Money Laundering training compliance

Employee Training

Deliver our leading AML and casino-specific online courses to stay compliant with national and state standards

Streamline training operations, increase employee effectiveness, and reduce liability with our LMS for casinos

Simplify incident reporting to OSHA and reduce risk with detailed investigation management

Employee Scheduling

Equip your employees with a mobile app to manage their schedules and simplify your 24/7 staff scheduling

Career & Technical Education NEW

Industrial Manufacturing

Chemical Processing

Pulp & Paper

Food & Beverage NEW

Utilities NEW

Renewables NEW

Distribution & Logistics

Distribution & Warehousing NEW

Public Safety

EMS Agencies

911 Emergency Communications

State Government - Fire Departments

State Government - Law Enforcement

Local Government

Architecture & Engineering

Facilities Management

Course Center

Success Stories

Speak to an Expert

Resource Center

Expert insights to boost training

Resource type

Course Catalogs

Whitepapers/Guides

Product Brochures

Acquisitions

Vector Cares

Executive Team

Industry Honors

Elevate Training, Elevate Success

Firefighter

See All Industrial Courses

See All AEC Courses

See All Facilities Courses

See All Casino Courses

OSHA Hazard Communication Standard and Program

September 9, 2017

Resource : blog industry : industrial tags : vector ehs management.

When the Hazard Communication Standard (HCS) was published by OSHA in 1983, it represented a decade of painstaking, but vital, rulemaking activity.

More than thirty years have elapsed since the rule was published. And yet, HCS remains one of the most important and relevant US occupational safety and health standards. The Hazard Communication Standard (29 CFR 1910.1200) , last updated in 2012 for GHS alignment , applies to a wide spectrum of workplaces and industries, and is considered one of the crown jewels in OSHA’s mission to protect workers on the job.

Convergence Training is a training solutions provider with a long history of creating safety and health training solutions.

Click the links to learn more about our training management solutions, safety and health eLearning course libraries, and custom training solutions.

Download our FREE Guide to Effective Safety Training

Background of the Hazard Communication Standard

The HCS is also called the Right-to-Know Law, as the intent of the Standard was to ensure workers had the legal right to know about chemical hazards in their workplaces. Prior to the HCS, employees often worked with chemical substances without information on how to avoid health and safety hazards. Lacking this knowledge, employees frequently had serious acute chemically-related injuries, and were unaware of long-term effects, such as cancer-causing chemical products, found on the job.

The law was a breakthrough in workplace safety, as it required chemical manufacturers and employers to relay chemical hazard information to employees. Apart from minor amendments through the years, there were no major revisions to the HCS. But, in 2012, OSHA made changes to modify the HCS to align with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

The GHS-aligned HCS (or HazCom 2012) does not impact the framework or scope of the “old” HCS, but it does help ensure consistency in conveying chemical information to workers. OSHA has stated about the alignment with GHS, “The Standard that gave workers the right to know, now gives them the right to understand.”

The GHS update allows for a more streamlined and consistent language in communicating hazards, which really does give workers and employers a better opportunity to understand chemical hazards. And as it builds upon the existing HazCom framework, the transition has been fairly easily for employers.

What is the Hazard Communication Framework?

Under the HazCom standard, a multi-pronged approach is used to convey chemical information to workers.

These include hazard information from chemical manufacturers, a written Hazard Communication program, safety data sheets, and Hazard Communication training for employees, each of which is described more closely below.

Hazard Information from Chemical Manufacturers

Chemical manufacturers and importers of chemicals have requirements under the HCS to examine their products for hazards and then provide information on those hazards. Previously these entities were required to evaluate the hazards of their products, but often that was a fuzzy and confusing process, with no governing or clear methodology for evaluation.

Now, under provisions of the newly aligned HazCom 2012, chemical manufacturers must classify health and physical chemical hazards according to the GHS criteria set forth in the Standard ( Appendices A and B of 1910.1200 ).

Then they must convey the hazard information downstream to those that purchase or use their chemical substances. Manufacturers and importers of these products provide this hazard information via labels on product containers and through safety data sheets.

This sample from our online Hazard Communication training course explains the different parts of an SDS.

Under HazCom 2012, these manufacturer’s labels and safety data sheets now follow a consistent format, which is composed of various pictograms, signal words and precautionary statements to identify hazards, as well as uniform language and format.

Written Hazard Communication Program

Employers have several responsibilities to relay chemical hazards to workers under the HCS, among these requirements is a Written Hazard Communication Program. (Note: A binder stuffed full of nothing but safety data sheets is not sufficient to meet the obligations of this part of the Standard. The Written Hazard Communication Program is far more than that.)

Detailed explanations can be found in 1910.1200(e) . But in general, the program consists of policies which describe how the employer will meet the requirements of the Hazard Communication Standard. An inventory list of the chemicals found in the workplace should be included in the written program, along with policies that cover the methods the employer will use to meet employee training, secondary container labeling, and other obligations under the Standard.

In addition, non-routine tasks that expose employees to chemical hazards, and the ways employers will use to inform employees of those hazards, is to be included in the written program.

If you have a multi-employer workplace, such as employees of a construction contractor working at your company, and there is a chance that those other employees may be exposed to your chemical hazards, you’ll need to cover that in the HCS written program. How will you provide those other employees information about your company’s chemical hazards and access to your safety data sheets? And what precautions do they need to take under normal working conditions and foreseeable emergencies when working at your company? These should be answered in your HCS written program.

And finally, like written programs for other standards, the HCS written program should be available to employees upon request, as well as available to OSHA, if they come calling. (In fact, it is usually one of the first programs OSHA asks for if they perform an inspection.)

Safety Data Sheets

Prior to the HazCom 2012, these were called, “material safety data sheets” or MSDS. To be sure, MSDS contained ample chemical information on fire, spill and first aid response, as well as the hazards of the chemical and necessary PPE, but they were not uniform in language or construction. It was often very challenging to read MSDSs and rapidly grasp any vital hazard information—especially during a chemical emergency.

The provisions of the HazCom 2012 alignment require these to be uniform, in a neatly and easily decipherable 16-section format , which uses consistent language. For example, hazard information is clearly laid out in Section 2, which is quickly found by anyone examining the document.

With the 2013 HazCom alignment, OSHA changed the name of these to, “Safety Data Sheets” or SDS. (That is probably the most confusing part of the entire Standard update, as many of us still want to say, “MSDS.”)

As noted earlier, SDS are created by chemical manufacturers, but employers must keep a copy for each hazardous chemical in the workplace. According to the Standard, employees must have access to these at any time throughout their shift. If you opt to keep your SDS digitally, the standard allows for that--as long as all employees can obtain them without any barriers, such as passwords on computers preventing access.

OSHA is very straightforward about this requirement, stating, “The employer shall maintain in the workplace copies of the required safety data sheets for each hazardous chemical, and shall ensure that they are readily accessible during each work shift to employees when they are in their work area(s).

Hazard Communication Training

The HazCom Standard requires the employers provide “effective information and training” on hazardous chemicals in their work area. Employers have a significant responsibility in this regard, as Hazard Communication training is one of the primary methods to keep workers safe during the use, handling and storage of chemicals.

If employees aren’t properly made aware of the workplace chemical hazards, disastrous consequences can occur. Your HazCom training, therefore, should be very thorough.

OSHA has a rather comprehensive list pertaining to HCS training requirements, which include:

- Requirements and purpose of the Hazard Communication Standard.

- Operations in the employees’ work areas where hazardous chemicals are present.

- Location, purpose and availability of the Written Hazard Communication Program, as well as the list of hazardous chemicals, and SDS.

- How to detect releases or presence of hazardous chemicals in the work area (such as odor, appearance of fumes or mist).

- The physical and health hazards of chemicals found in the workplace, including hazard classifications, and associated pictograms, signal words, and terminology.

- Measures employees can use to protect from chemical hazards, such as PPE, ventilation, administrative or engineering controls, etc.

- Details and explanation of labels on shipped containers, workplace labeling and SDS.

HCS training is to be given to workers at the time of their initial assignment, and if new chemical hazards are found in the workplace that were not addressed in previous training. Retraining is also given when a worker has exposure to new chemical hazards through a change in job duties or work area.

The Hazard Communication Standard was built with an excellent foundation through providing information and training to workers. Now enhanced by the 2012 alignment with the GHS, the ease and function of the Standard have been increased. Understanding the Standard and its updates, is vital to putting this into practice in your workplace.

As you can see from the list above, comprehensive training is necessary to meet the requirements of the Standard, as well as protect your workers from chemical hazards.

This online hazard communication training course is a good addition to your employee HazCom training program.

In addition to everything written above, you may also find these Haz-Com related articles helpful:

- GHS Label Requirements, Symbols, and Classifications

- Who Has Hazard Communication Duties on the Job?

Blog May 14 2024 -->

Osha's "fatal four" in construction: leading causes of…, whitepapers & guides march 1 2024 -->, the power of online maintenance training guide, blog april 24 2023 -->, 10 daily workplace safety tips in manufacturing, want to know more, reach out and a vector solutions representative will respond back to help answer any questions you might have..

JavaScript is required...

Please enable Javascript in order to use PubChem website.

GHS Classification (Rev.10, 2023) Summary

- UNECE GHS (Rev.10, 2023)

- UNECE GHS (Rev.9, 2021)

- UNECE GHS (Rev.8, 2019)

- UNECE GHS (Rev.7, 2017)

- UNECE GHS (Rev.6, 2015)

- Hazard Class Pictograms

- GHS Hazard Statements

- Precautionary Statements

Hazard Class Pictograms ☝

Note: All pictograms are shown in svg format in the page. The corresponding gif images are also available, e.g. https://pubchem.ncbi.nlm.nih.gov/images/ghs/GHS08.gif .

GHS Hazard Statements ☝

Precautionary statements ☝, general precautionary statements.

P101: If medical advice is needed, have product container or label at hand. P102: Keep out of reach of children. P103: Read carefully and follow all instructions.

Prevention Precautionary Statements

P201: ( Obsolete ) Obtain special instructions before use. P202: ( Obsolete ) Do not handle until all safety precautions have been read and understood. P203: Obtain, read and follow all safety instructions before use. P210: Keep away from heat, hot surface, sparks, open flames and other ignition sources. No smoking. P211: Do not spray on an open flame or other ignition source. P212: Avoid heating under confinement or reduction of the desensitized agent. P220: Keep away from clothing and other combustible materials. P221: ( Obsolete ) Take any precaution to avoid mixing with combustibles/... P222: Do not allow contact with air. P223: Do not allow contact with water. P230: Keep wetted with ... P231: Handle and store contents under inert gas/... P232: Protect from moisture. P233: Keep container tightly closed. P234: Keep only in original container. P235: Keep cool. P236: Keep only in original packaging; Division .. in the transport configuraion. P240: Ground/bond container and receiving equipment. P241: Use explosion-proof [electrical/ventilating/lighting/.../] equipment. P242: Use only non-sparking tools. P243: Take precautionary measures against static discharge. P244: Keep valves and fittings free from oil and grease. P250: Do not subject to grinding/shock/friction/... P251: Do not pierce or burn, even after use. P260: Do not breathe dust/fume/gas/mist/vapors/spray. P261: Avoid breathing dust/fume/gas/mist/vapors/spray. P262: Do not get in eyes, on skin, or on clothing. P263: Avoid contact during pregnancy/while nursing. P264: Wash hands [and ...] thoroughly after handling. P265: Do not touch eyes. P270: Do not eat, drink or smoke when using this product. P271: Use only outdoors or in a well-ventilated area. P272: Contaminated work clothing should not be allowed out of the workplace. P273: Avoid release to the environment. P280: Wear protective gloves/protective clothing/eye protection/face protection/hearing protection/... P281: ( Obsolete )Use personal protective equipment as required. P282: Wear cold insulating glovesand either face shield or eye protection. P283: Wear fire resistant or flame retardant clothing. P284: [In case of inadequate ventilation] Wear respiratory protection. P285: ( Obsolete ) In case of inadequate ventilation wear respiratory protection. P231+P232: Handle and store contents under inert gas/... Protect from moisture. P264+P265: Wash hands [and ...] thoroughly after handling. Do not touch eyes. P235+P410: ( Obsolete ) Keep cool. Protect from sunlight.

Response Precautionary Statements

P301: IF SWALLOWED: P302: IF ON SKIN: P303: IF ON SKIN (or hair): P304: IF INHALED: P305: IF IN EYES: P306: IF ON CLOTHING: P307: ( Obsolete ) IF exposed: P308: IF exposed or concerned: P309: ( Obsolete ) IF exposed or if you feel unwell P310: ( Obsolete ) Immediately call a POISON CENTER or doctor/physician. P311: ( Obsolete ) Call a POISON CENTER or doctor/... P312: ( Obsolete ) Call a POISON CENTER or doctor/... if you feel unwell. P313: ( Obsolete ) Get medical advice/attention. P314: ( Obsolete ) Get medical advice/attention if you feel unwell. P315: ( Obsolete ) Get immediate medical advice/attention. P316: Get emergency medical help immediately. P317: Get emergency medical help. P318: if exposed or concerned, get medical advice. P319: Get medical help if you feel unwell. P320: Specific treatment is urgent (see ... on this label). P321: Specific treatment (see ... on this label). P322: ( Obsolete ) Specific measures (see ...on this label). P330: Rinse mouth. P331: Do NOT induce vomiting. P332: IF SKIN irritation occurs: P333: If skin irritation or rash occurs: P334: Immerse in cool water [or wrap in wet bandages]. P335: Brush off loose particles from skin. P336: Thaw frosted parts with lukewarm water. Do not rub affected area. P337: If eye irritation persists: P338: Remove contact lenses, if present and easy to do. Continue rinsing. P340: Remove person to fresh air and keep comfortable for breathing. P341: ( Obsolete ) If breathing is difficult, remove victim to fresh air and keep at rest in a position comfortable for breathing. P342: If experiencing respiratory symptoms: P350: ( Obsolete ) Gently wash with plenty of soap and water. P351: Rinse cautiously with water for several minutes. P352: Wash with plenty of water/... P353: Rinse skin with water [or shower]. P354: Immediately rinse with water for several minutes. P360: Rinse immediately contaminated clothing and skin with plenty of water before removing clothes. P361: Take off immediately all contaminated clothing. P362: Take off contaminated clothing. P363: Wash contaminated clothing before reuse. P364: And wash it before reuse. P370: In case of fire: P371: In case of major fire and large quantities: P372: Explosion risk. P373: DO NOT fight fire when fire reaches explosives. P374: ( Obsolete ) Fight fire with normal precautions from a reasonable distance. P375: Fight fire remotely due to the risk of explorsion. P376: Stop leak if safe to do so. P377: Leaking gas fire: Do not extinguish, unless leak can be stopped safely. P378: Use ... to extinguish. P380: Evacuate area. P381: In case of leakage, eliminate all ignition sources. P390: Absorb spillage to prevent material damage. P391: Collect spillage. P301+P310: ( Obsolete ) IF SWALLOWED: Immediately call a POISON CENTER/doctor/... P301+P312: ( Obsolete ) IF SWALLOWED: call a POISON CENTER/doctor/... IF you feel unwell. P301+P316: IF SWALLOWED: Get emergency medical help immediately. P301+P317: IF SWALLOWED: Get medical help. P301+P330+P331: IF SWALLOWED: Rinse mouth. Do NOT induce vomiting. P302+P317: IF ON SKIN: Get medical help. P302+P334: IF ON SKIN: Immerse in cool water or wrap in wet bandages. P302+P335+P334: Brush off loose particles from skin. Immerse in cool water [or wrap in wet bandages]. P302+P350: ( Obsolete ) IF ON SKIN: Gently wash with plenty of soap and water. P302+P352: IF ON SKIN: wash with plenty of water/... P302+P361+P354: IF ON SKIN: Take off Immediately all contaminated clothing. Immediately rinse with water for several minutes. P303+P361+P353: IF ON SKIN (or hair): Take off Immediately all contaminated clothing. Rinse SKIN with water [or shower]. P304+P312: ( Obsolete ) IF INHALED: Call a POISON CENTER/doctor/... if you feel unwell. P304+P317: IF INHALED: Get medical help. P304+P340: IF INHALED: Remove person to fresh air and keep comfortable for breathing. P304+P341: ( Obsolete ) IF INHALED: If breathing is difficult, remove victim to fresh air and keep at rest in a position comfortable for breathing. P305+P351+P338: IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses if present and easy to do - continue rinsing. P305+P354+P338: IF IN EYES: Immediately rinse with water for several minutes. Remove contact lenses if present and easy to do. Continue rinsing. P306+P360: IF ON CLOTHING: Rinse Immediately contaminated CLOTHING and SKIN with plenty of water before removing clothes. P308+P316: IF exposed or concerned: Get emergency medical help immediately. P307+P311: ( Obsolete ) IF exposed: call a POISON CENTER or doctor/physician. P308+P311: ( Obsolete ) IF exposed or concerned: Call a POISON CENTER/doctor/... P308+P313: ( Obsolete ) IF exposed or concerned: Get medical advice/attention. P309+P311: ( Obsolete ) IF exposed or if you feel unwell: call a POISON CENTER or doctor/physician. P332+P313: ( Obsolete ) IF SKIN irritation occurs: Get medical advice/attention. P332+P317: If skin irritation occurs: Get medical help. P333+P317: If skin irritation or rash occurs: Get medical help. P336+P317: Immediately thaw frosted parts with lukewarm water. Do not rub affected area. Get medical help. P337+P317: If eye irritation persists: Get medical help. P342+P316: If experiencing respiratory symptoms: Get emergence medical help immediately. P333+P313: ( Obsolete ) IF SKIN irritation or rash occurs: Get medical advice/attention. P335+P334: ( Obsolete ) Brush off loose particles from skin. Immerse in cool water/wrap in wet bandages. P337+P313: ( Obsolete ) IF eye irritation persists: Get medical advice/attention. P342+P311: ( Obsolete ) IF experiencing respiratory symptoms: Call a POISON CENTER/doctor/... P361+P364: Take off immediately all contaminated clothing and wash it before reuse. P362+P364: Take off contaminated clothing and wash it before reuse. P370+P376: in case of fire: Stop leak if safe to do so. P370+P378: In case of fire: Use ... to extinguish. P370+P380: ( Obsolete ) In case of fire: Evacuate area. P370+P380+P375: In case of fire: Evacuate area. Fight fire remotely due to the risk of explosion. P371+P380+P375: In case of major fire and large quantities: Evacuate area. Fight fire remotely due to the risk of explosion. P370+P372+P380+P373: In case of fire: Explosion risk. Evacuate area. DO NOT fight fire when fire reaches explosives. P370+P380+P375[+P378]: In case of fire: Evacuate area. Fight fire remotely due to the risk of explosion. [Use...to extinguish].]

Storage Precautionary Statements

P401: Store in accordance with ... P402: Store in a dry place. P403: Store in a well-ventilated place. P404: Store in a closed container. P405: Store locked up. P406: Store in corrosive resistant/... container with a resistant inner liner. P407: Maintain air gap between stacks or pallets. P410: Protect from sunlight. P411: Store at temperatures not exceeding ... °C/...°F. P412: Do not expose to temperatures exceeding 50 °C/ 122 °F. P413: Store bulk masses greater than ... kg/...lbs at temperatures not exceeding ... °C/...°F. P420: Store separately. P422: ( Obsolete ) Store contents under ... P402+P404: Store in a dry place. Store in a closed container. P403+P233: Store in a well-ventilated place. Keep container tightly closed. P403+P235: Store in a well-ventilated place. Keep cool. P410+P403: Protect from sunlight. Store in a well-ventilated place. P410+P412: Protect from sunlight. Do not expose to temperatures exceeding 50 °C/122°F. P411+P235: ( Obsolete ) Store at temperatures not exceeding ... °C/...°F. Keep cool.

Disposal Precautionary Statements

P501: Dispose of contents/container to ... P502: Refer to manufacturer or supplier for information on recovery or recycling P503: Refer to manufacturer/supplier... for information on disposal/recovery/recycling.

- What You Need to Know About OSHA’s Updated Hazard Communication (Chemical Right-to-Know) Standard