- DSpace@MIT Home

- MIT Libraries

- Graduate Theses

Additive manufacturing (3 D printing) : challenges and opportunities for large scale adoption

Alternative title

Other contributors, terms of use, description, date issued, collections.

A critical review of 3D printing in construction: benefits, challenges, and risks

- Review Article

- Published: 10 March 2020

- Volume 20 , article number 34 , ( 2020 )

Cite this article

- S. El-Sayegh ORCID: orcid.org/0000-0002-9127-0318 1 ,

- L. Romdhane ORCID: orcid.org/0000-0001-8509-2386 2 &

- S. Manjikian 1

16k Accesses

122 Citations

Explore all metrics

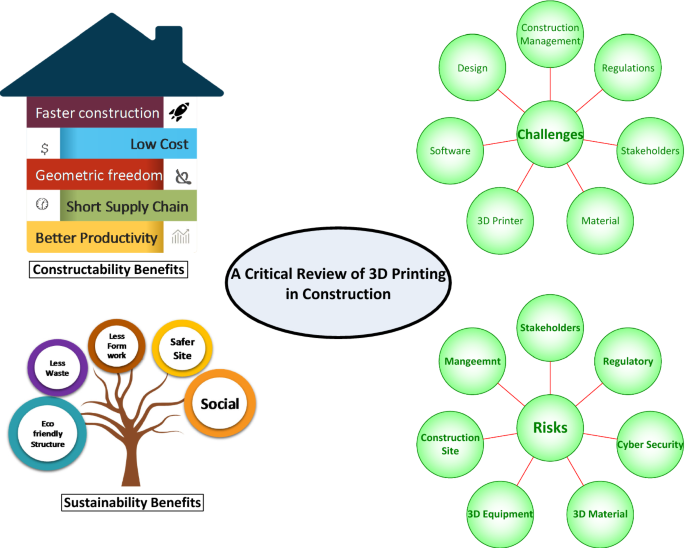

This paper provides a critical review of the related literature on 3D printing in construction. The paper discusses and evaluates the different 3D printing techniques in construction. The paper also discusses and categorizes the benefits, challenges, and risks of 3D printing in construction. The use of 3D printing technology offers several advantages over traditional methods. However, it comes with its own additional challenges and risks. The main benefits of 3D printing in construction include constructability and sustainability benefits. The challenges are categorized into seven groups. The main challenges, found through the literature, are material related. The most cited challenges are material printability, buildability, and open time. Additionally, scalability, structural integrity, and lack of codes and regulations are frequently cited as major challenges. The additional risks are categorized into seven groups: 3D printing material, 3D printing equipment, construction site, and environment, management, stakeholders, regulatory and economic, and cybersecurity risks. The paper fills a gap in the literature as it addresses a new aspect of 3D printing, which is risk. The paper also provides some insights, recommendations, and future research ideas.

Graphic abstract

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

3D printing in construction: state of the art and applications

3D Printing for Construction: A Systematic Review of Its Sustainability

3D Printing in Construction Industry: A State of Art

Gerbert P, Castagnino S, Rothballer C, Renz A, Filitz R. The transformative power of building information modeling, March 08, 2016 Boston Consulting Group. 2016. https://www.bcgperspectives.com/content/articles/engineered-products-project-business-digital-engineering-construction/ . Accessed 28 Jan 2019.

Horvath J. Mastering 3D printing (technology in action). Berkeley: Apress; 2014. https://doi.org/10.1007/978-1-4842-0025-4 .

Book Google Scholar

Maskuriy R, Selamat A, Maresova P, Krejcar A, Olalekan David O. Industry 4.0 for the construction industry: review of management perspective. Economies. 2019;68(7):4. https://doi.org/10.3390/economies7030068 .

Article Google Scholar

Bock T. The future of construction automation: technological disruption and the upcoming ubiquity of robotics. Autom Constr. 2015;59:113–21. https://doi.org/10.1016/j.autcon.2015.07.022 .

García de Soto B, Agustí-Juan I, Hunhevicz J, Joss S, Graser K, Habert G, Adey B. Productivity of digital fabrication in construction: cost and time analysis of a robotically built wall. Autom Constr. 2018;92:297–311. https://doi.org/10.1016/j.autcon.2018.04.004 .

Brettel M, Friederichsen N, Keller M, Rosenberg M. How virtualization, decentralization and network building change the manufacturing landscape: an industry 4.0 perspective. Int J Mech Aerosp Ind Mechatron Manuf Eng. 2014;8(1):37–44.

Google Scholar

Oesterreich TD, Teuteberg F. Understanding the implications of digitisation and automation in the context of industry 4.0: a triangulation approach and elements of a research agenda for the construction industry. Comput Ind. 2016;83:121–39. https://doi.org/10.1016/j.compind.2016.09.006 .

Dallasegaa P, Raucha E, Linderb C. Industry 4.0 as an enabler of proximity for construction supply chains: a systematic literature review. Comput Ind. 2018;99:205–25. https://doi.org/10.1016/j.compind.2018.03.039 .

Alaloul WS, Liew MS, Zawawi NW, Mohammed BS. Industry revolution IR 4.0: future opportunities and challenges in construction industry. In: MATEC web of conferences 203, 2010. 2018. https://doi.org/10.1051/matecconf/201820302010 .

Hager I, Golonka A, Putanowicz R. 3D printing of buildings and building components as the future of sustainable construction? Procedia Eng. 2016;151:292–9. https://doi.org/10.1016/j.proeng.2016.07.357 .

Noorani R. 3D printing: technology, applications, and selection. Boca Raton: CRC Press; 2018.

Kietzmann J, Pitt L, Berthon P. Disruptions, decisions, and destinations: enter the age of 3D printing and additive manufacturing. Bus Horiz. 2015;58(2):209–15. https://doi.org/10.1016/j.bushor.2014.11.005 .

Davtalab O, Kazemian A, Khoshnevis B. Perspectives on a BIM-integrated software platform for robotic construction through contour crafting. Autom Constr. 2018;89:13–23. https://doi.org/10.1016/j.autcon.2018.01.006 .

Camacho D, Clayton P, O’Brien W, Seepersad C, Juenger M, Ferron R, Salamone S. Applications of additive manufacturing in the construction industry: a forward-looking review. Autom Constr. 2018;89:110–9. https://doi.org/10.1016/j.autcon.2017.12.031 .

Yossef M, Chen A. Applicability and limitations of 3D printing for civil structures. Civ Constr Environ Eng Conf Present Proc. 2015;35:87–99.

Lim S, Buswell RA, Le TT, Austin SA, Gibb AG, Thorpe T. Developments in construction-scale additive manufacturing processes. Autom Constr. 2011;21:262–8. https://doi.org/10.1016/j.autcon.2011.06.010 .

Wu P, Wang J, Wang X. A critical review of the use of 3D printing in the construction industry. Autom Constr. 2016;68:21–31. https://doi.org/10.1016/j.autcon.2016.04.005 .

PMBOK. A guide to the project management body of knowledge. 6th ed. Newtown Square: Project Management Institute Standards Committee, PMI; 2017.

Barber R. Understanding internally generated risks in projects. Int J Project Manag. 2005;23(8):584–90. https://doi.org/10.1016/j.ijproman.2005.05.006 .

ANDI. The importance and allocation of risks in Indonesian construction projects. Constr Manag Econ. 2006;24(1):69–80. https://doi.org/10.1080/01446190500310338 .

El-Sayegh S. Risk assessment and allocation in the UAE construction industry. Int J Project Manag. 2008;26(4):431–8. https://doi.org/10.1016/j.ijproman.2007.07.004 .

Jung K-Y, Roh M-S. A study for an appropriate risk management of new technology deployment in nuclear power plants. Ann Nucl Energy. 2016;99:157–64. https://doi.org/10.1016/j.anucene.2016.08.013 .

Conner BP, Manogharan GP, Meyers KL. An assessment of implementation of entry-level 3D printers from the perspective of small businesses. Rapid Prototyp J. 2015;21(5):582–97. https://doi.org/10.1108/RPJ-09-2014-0132 .

Malone D. 2017. https://www.bdcnetwork.com/europe%E2%80%99s-first-3d-printed-building-has-been-completed . Accessed 22 Feb 2019.

Paul S, Van Zijl G, Tan M, Gibson I. A review of 3D concrete printing systems and materials properties: current status and future research prospects. Rapid Prototyp J. 2018;24(4):784–98. https://doi.org/10.1108/RPJ-09-2016-0154 .

Ghaffar S, Corker J, Fan M. Additive manufacturing technology and its implementation in construction as an eco-innovative solution. Autom Constr. 2018;93:1–11. https://doi.org/10.1016/j.autcon.2018.05.005 .

Uppalla S, Tadikamalla M. A review on 3D printing of concrete—the future of sustainable construction. I-Manager’s J Civ Eng. 2017;7(3):49–62. https://doi.org/10.26634/jce.7.3.13610 .

Labonnote N, Rønnquist A, Manum B, Rüther P. Additive construction: state-of-the-art, challenges and opportunities. Autom Constr. 2016;72:347–66. https://doi.org/10.1016/j.autcon.2016.08.026 .

Bos F, Wolfs R, Ahmed Z, Salet T. Additive manufacturing of concrete in construction: potentials and challenges of 3D concrete printing. Virtual Phys Prototyp. 2016;11(3):209–25. https://doi.org/10.1080/17452759.2016.1209867 .

Tay YWD, Panda B, Paul SC, Noor Mohamed NA, Tan MJ, Leong KF. 3D printing trends in building and construction industry: a review. Virtual Phys Prototyp. 2017;12(3):261–76.

Shakor P, Nejadi S, Paul G, Malek S. Review of emerging additive manufacturing technologies in 3D printing of cementitious materials in the construction industry. Front Built Environ. 2019;4:85.

Hamidi F, Aslani F. Additive manufacturing of cementitious composites: materials, methods, potentials, and challenges. Constr Build Mater. 2019;218:582–609. https://doi.org/10.1016/j.conbuildmat.2019.05.140 .

ISO/ASTM52900-15. Standard terminology for additive manufacturing—general principles—terminology. West Conshohocken: ASTM International; 2015.

Gibson I, Rosen D, Stucker B. Additive manufacturing technologies: 3D printing, rapid prototyping, and direct digital manufacturing. 2nd ed. New York: Springer; 2015. https://doi.org/10.1007/978-1-4939-2113-3 .

D-shape.com. D-shape building process. 2019. https://d-shape.com/the-technology/d-shape-building-process/ . Accessed 7 Apr 2019.

Xu J, Ding L, Love P. Digital reproduction of historical building ornamental components: from 3D scanning to 3D printing. Autom Constr. 2017;76:85–96. https://doi.org/10.1016/j.autcon.2017.01.010 .

Yeon J, Kang J, Yan W. Spall damage repair using 3D printing technology. Autom Constr. 2018;89:266–74. https://doi.org/10.1016/j.autcon.2018.02.003 .

Mueller RP, Howe S, Kochmann D, Ali H, Andersen C, Burgoyne H, Chambers W, Clinton R, De Kestellier X, Ebelt K, Gerner S, Hofmann D, Hogstrom K, Ilves E, Jerves A, Keenan R, Keravala J, Khoshnevis B, Lim S, Metzger P, Meza L, Nakamura T, Nelson A, Partridge H, Pettit D, Pyle R, Reiners E, Shapiro A, Singer R, Tan W-L, Vazquez N, Wilcox B, Zelhofer A. Automated additive construction (AAC) for earth and space using in-situ resources. In: Proceedings of the fifteenth biennial ASCE aerospace division international conference on engineering, science, construction, and operations in challenging environments (Earth & Space 2016). Reston: American Society of Civil Engineers; 2016. http://oro.open.ac.uk/45865/1/3Dadditive_paper_final.pdf . Accessed 15 Dec 2019.

Ingaglio J, Fox J, Naito CJ, Bocchini P. Material characteristics of binder jet 3D printed hydrated CSA cement with the addition of fine aggregates. Constr Build Mater. 2019;206:494–503.

Shakor P, Sanjayan J, Nazari A, Nejadi S. Modified 3D printed powder to cement-based material and mechanical properties of cement scaffold used in 3D printing. Constr Build Mater. 2017;138:398–409.

Lowke D, Dini E, Perrot A, Weger D, Gehlen C, Dillenburger B. Particle-bed 3D printing in concrete construction: possibilities and challenges. Cem Concr Res. 2018;112:50–65. https://doi.org/10.1016/j.cemconres.2018.05.018 .

Khoshnevis B, Hwang D, Yao KT, Yeh Z. Mega-scale fabrication by contour crafting. Int J Ind Syst Eng. 2006;1(3):301–20. https://doi.org/10.1504/IJISE.2006.009791 .

Craveiro F, Bartolo H, Gale A, Duarte J, Bartolo P. A design tool for resource-efficient fabrication of 3D-graded structural building components using additive manufacturing. Autom Constr. 2017;82:75–83. https://doi.org/10.1016/j.autcon.2017.05.006 .

Duballet R, Baverel O, Dirrenberger J. Classification of building systems for concrete 3D printing. Autom Constr. 2017;83:247–58. https://doi.org/10.1016/j.autcon.2017.08.018 .

Gosselin C, Duballet R, Roux P, Gaudillière N, Dirrenberger J, Morel P. Large-scale 3D printing of ultra-high performance concrete: a new processing route for architects and builders. Mater Des. 2016;100:102–9. https://doi.org/10.1016/j.matdes.2016.03.097 .

Zareiyan B, Khoshnevis B. Effects of interlocking on interlayer adhesion and strength of structures in 3D printing of concrete. Autom Constr. 2017;83:212–21. https://doi.org/10.1016/j.autcon.2017.08.019 .

Apis Cor. We print buildings. http://www.apis-cor.com/en/ . Accessed 15 Dec 2019.

Zhang X, Li M, Lim J, Weng Y, Tay Y, Pham H, Pham Q. Large-scale 3D printing by a team of mobile robots. Autom Constr. 2018;95:98–106. https://doi.org/10.1016/j.autcon.2018.08.004 .

Barnett E, Gosselin C. Large-scale 3D printing with a cable-suspended robot. Addit Manuf. 2015;7:27–44. https://doi.org/10.1016/j.addma.2015.05.001 .

https://www.constructionweekonline.com/products-services/257548-video-cobod-set-to-ship-worlds-largest-3d-printer-to-saudi-arabia .

Kothman I, Faber N. How 3D printing technology changes the rules of the game. J Manuf Technol Manag. 2016;27(7):932–43. https://doi.org/10.1108/JMTM-01-2016-0010 .

Feng L, Yuhong L. Study on the status quo and problems of 3D printed buildings in China. Glob J Hum Soc Sci H Interdiscip. 2014;14(5):7–10.

3D Printers, WASP, Leading Company in the 3D printing industry. 2019. https://www.3dwasp.com/en/ . Accessed 15 Dec 2019.

Le T, Austin S, Lim S, Buswell R, Gibb A, Thorpe T. Mix design and fresh properties for high-performance printing concrete. Mater Struct. 2012;45(8):1221–32. https://doi.org/10.1617/s11527-012-9828-z .

Buswell RA, Leal de Silva WR, Jones SZ, Dirrenberger J. 3D printing using concrete extrusion: a roadmap for research. Cem Concr Res. 2018;112:37–49.

Cemex Ventures. Benefits of 3D printing in construction. 2019. https://www.cemexventures.com/benefits-of-3d-printing-in-construction/ . Accessed 19 Jan 2019.

Le T, Austin S, Lim S, Buswell R, Law R, Gibb A, Thorpe T. Hardened properties of high-performance printing concrete. Cem Concr Res. 2012;42(3):558–66. https://doi.org/10.1016/j.cemconres.2011.12.003 .

Papachristoforou M, Mitsopoulos V, Stefanidou M. Evaluation of workability parameters in 3D printing concrete. Procedia Struct Integr. 2018;10:155–62. https://doi.org/10.1016/j.prostr.2018.09.023 .

Wangler T, Lloret E, Reiter L, Hack N, Gramazio F, Kohler M, Flatt R. Digital concrete: opportunities and challenges. Rilem Tech Lett. 2016;1:67–75. https://doi.org/10.21809/rilemtechlett.2016.16 .

Hambach M, Volkmer D. Properties of 3D-printed fiber-reinforced portland cement paste. Cem Concr Compos. 2017;79:62–70. https://doi.org/10.1016/j.cemconcomp.2017.02.001 .

Doo-Yeol Y, Young-Soo Y. A review on structural behavior, design, and application of ultra-high-performance fiber-reinforced concrete. Int J Concr Struct Mater. 2016;10(2):125–42. https://doi.org/10.1007/s40069-016-0143-x .

Ducoulombier N, Chateau C, Bornert M, Caron J-F, Weitkamp T, Perrin J. Characterisation and modelling of interfacial damage in fibre reinforced concrete for 3D printing in construction. In: 10th international conference on fracture mechanics of concrete and concrete structures, June 2019, Bayonne, France. https://doi.org/10.21012/FC10.235562 .

Bos F, Bosco E, Salet T. Ductility of 3D printed concrete reinforced with short straight steel fibers. Virtual Phys Prototyp. 2019;14(2):160–74.

Feng P, Meng X, Zhang H. Mechanical behavior of FRP sheets reinforced 3D elements printed with cementitious materials. Compos Struct. 2015;134:331–42.

Arayici Y, Egbu CO, Coates SP. Building information modelling (BIM) implementation and remote construction projects: issues, challenges, and critiques. J Inf Technol Constr. 2012;17:75–92.

Robichaud L, Anantatmula VS. Greening project management practices for sustainable construction. J Manag Eng. 2011;27(1):48–57. https://doi.org/10.1061/(ASCE)ME.1943-5479.0000030 .

Feng P, Meng X, Chen J, Ye L. Mechanical properties of structures 3D printed with cementitious powders. Constr Build Mater. 2015;93:486–97. https://doi.org/10.1016/j.conbuildmat.2015.05.132 .

Zhang J, Hu Z. BIM- and 4D-based integrated solution of analysis and management for conflicts and structural safety problems during construction: 1. Principles and methodologies. Autom Constr. 2011;20(2):155–66. https://doi.org/10.1016/j.autcon.2010.09.013 .

World Economic Forum. Winsun: demonstrating the viability of 3D printing at the construction scale. 2016. https://futureofconstruction.org/case/winsun/ . Accessed 15 Dec 2019.

Dubai Future Foundation. Dubai 3D printing strategy. www.dubaifuture.gov.ae/our-initiatives/dubai-3d-printing-strategy/#1458229619399-0dfdadfa-8f328fc7-fbc6 . Accessed 1 Nov 2018.

D Printhuset. The construction of Europe’s first 3D Printed building has begun and is almost complete. 3D Printhuset. http://www.3dprinthuset.dk/europes-first-3d-printed-building/ . Accessed 1 Nov 2018.

CyBe. Redefining construction by enabling 3D concrete printing by providing hardware, software, material, education, certification and business development. CyBe Construction. http://www.cybe.eu/ . Accessed 1 Nov 2018.

CNN Style. The world’s longest 3D-printed concrete bridge is finished. 2019. https://edition.cnn.com/style/article/shanghai-3d-printed-bridge-scli-intl/index.html . Accessed 2 Feb 2019.

Buswell RA, Soar RC, Gibb AGF, Thorpe A. Freeform construction: mega-scale rapid manufacturing for construction. Autom Constr. 2007;16(2):224–31. https://doi.org/10.1016/j.autcon.2006.05.002 .

Campbell T, Williams C, Ivanova O, Garrett B. Could 3D printing change the world? Technologies, potential, and implications of additive manufacturing. Atlantic Council. 2011. http://www.atlanticcouncil.org/images/files/publication_pdfs/403/101711_ACUS_3DPrinting.PDF . Accessed 15 Dec 2019.

Khoshnevis B. Automated construction by contour crafting—related robotics and information technologies. Autom Constr. 2004;13(1):5–19. https://doi.org/10.1016/j.autcon.2003.08.012 .

Chen Q, García de Soto B, Adey B. Construction automation: research areas, industry concerns and suggestions for advancement. Autom Constr. 2018;94:22–38. https://doi.org/10.1016/j.autcon.2018.05.028 .

WCED (World Commission on Environment and Development). Our common future (Oxford paperbacks). Oxford: Oxford University Press; 1987.

Karakhan AM, Gambatese JM. Identification, quantification, and classification of potential safety risk for sustainable construction in the United States. J Constr Eng Manag. 2017. https://doi.org/10.1061/(asce)co.1943-7862.0001302 .

Perrot A, Rangeard D, Courteille E. 3D printing of earth-based materials: processing aspects. Constr Build Mater. 2018;172:670–6. https://doi.org/10.1016/j.conbuildmat.2018.04.017 .

Zhang Z, Provis J, Reid A, Wang H. Geopolymer foam concrete: an emerging material for sustainable construction. Constr Build Mater. 2014;56:113–27. https://doi.org/10.1016/j.conbuildmat.2014.01.081 .

Xia M, Nematollahi B, Sanjayan J. Printability, accuracy and strength of geopolymer made using powder-based 3D printing for construction applications. Autom Constr. 2019;101:179–89. https://doi.org/10.1016/j.autcon.2019.01.013 .

OECD. Material resources, productivity and the environment. OECD green growth studies. Paris: OECD Publishing; 2015. https://doi.org/10.1787/9789264190504-en .

Zou P, Zhang G. Comparative study on the perception of construction safety risks in China and Australia. J Constr Eng Manag. 2009;135(7):620–7. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000019 .

Whirlwind Team. Impacts of 3D printing on the construction industry. https://www.whirlwindsteel.com/blog/impacts-of-3d-printing-on-the-construction-industry . Accessed 15 Dec 2019.

Costanzi C, Ahmed Z, Schipper H, Bos F, Knaack U, Wolfs R. 3D printing concrete on temporary surfaces: the design and fabrication of a concrete shell structure. Autom Constr. 2018;94:395–404. https://doi.org/10.1016/j.autcon.2018.06.013 .

Perkins I, Skitmore M. Three-dimensional printing in the construction industry: a review. Int J Constr Manag. 2015;15(1):1–9. https://doi.org/10.1080/15623599.2015.1012136 .

Panda B, Tay Y, Paul S, Tan M. Current challenges and future potential of 3D concrete printing. Mater Sci Eng Technol. 2018;49(5):666–73. https://doi.org/10.1002/mawe.201700279 .

Paul S, Tay Y, Panda B, Tan M. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch Civ Mech Eng. 2018;18(1):311–9. https://doi.org/10.1016/j.acme.2017.02.008 .

Bridges SM, Keiser K, Sissom N, Graves SJ. Cyber security for additive manufacturing. In: Proceedings of the 10th annual cyber and information security research conference article no. 14, New York, 2015. New York: ACM International Conference Proceedings Series; 2015. https://doi.org/10.1145/2746266.2746280 .

Berman B. 3D printing: the new industrial revolution. IEEE Eng Manag Rev. 2013. https://doi.org/10.1109/emr.2013.6693869 .

Shakor P, Nejadi S, Paul G. A study into the effect of different nozzles shapes and fibre-reinforcement in 3D printed mortar. Materials. 2019;12:1708. https://doi.org/10.3390/ma12101708 .

Kreiger MA, MacAllister BA, Wilhoit JM, Case MP. The current state of 3D printing for use in construction. In: Proceedings of the 2015 conference on autonomous and robotic construction of infrastructure, Ames, Iowa; 2015. pp. 149–158.

Hwang B, Shan M, Supa’at N. Green commercial building projects in Singapore: critical risk factors and mitigation measures. Sustain Cities Soc. 2017;30(7):237–47. https://doi.org/10.1016/j.scs.2017.01.020 .

El-Sayegh S, Manjikian S, Ibrahim A, Abouelyousr A, Jabbour R. Risk identification and assessment in sustainable construction projects in the UAE. Int J Constr Manag. 2018. https://doi.org/10.1080/15623599.2018.1536963 .

Robinson P. Project learning with 3D printing: 3D materials and construction possibilities. New York: Cavendish Square Publishing; 2018. https://ebookcentral.proquest.com/lib/aus-ebooks/reader.action?docID=5404812 . Accessed 7 Apr 2019. ISBN 9781502631473.

Zayed T, Amer M, Pan J. Assessing risk and uncertainty inherent in Chinese highway projects using AHP. Int J Project Manag. 2008;26(4):408–19. https://doi.org/10.1016/j.ijproman.2007.05.012 .

Al-Hajj A, Hamani K. Material waste in the UAE construction industry: main causes and minimization practices. Archit Eng Des Manag. 2011;7(4):221–35. https://doi.org/10.1080/17452007.2011.594576 .

Popov G, Lyon BK, Hollcroft B. Risk assessment: a practical guide to assessing operational risks. 2016. https://ebookcentral.proquest.com . Accessed 15 Dec 2019. ISBN-13: 978-1628251845.

Mathews K. Avoid common robotics hazards by following these 6 rules. 2019. Blog.robotiq.com. https://blog.robotiq.com/avoid-these-common-robotics-hazards-by-following-these-6-rules . Accessed 2 Feb 2019.

Chinniah Y. Robot safety: overview of risk assessment and reduction. Adv Robot Autom. 2016. https://doi.org/10.4172/2168-9695.1000139 .

Li R. An economic analysis on automated construction safety: internet of things, artificial intelligence and 3D printing. Singapore: Springer; 2017. https://doi.org/10.1007/978-981-10-5771-7 .

Salet T, Ahmed Z, Bos F, Laagland H. Design of a 3D printed concrete bridge by testing. Virtual Phys Prototyp. 2018;13(3):222–36. https://doi.org/10.1080/17452759.2018.1476064 .

Kartam N, Kartam S. Risk and its management in the Kuwaiti construction industry: a contractors’ perspective. Int J Project Manag. 2001;19(6):325–35. https://doi.org/10.1016/S0263-7863(00)00014-4 .

Tang W, Qiang M, Duffield C. Risk management in the Chinese construction industry. J Constr Eng Manag. 2007;133(12):944–56. https://doi.org/10.1061/(ASCE)0733-9364(2007)133:12(944) .

Chapman R. The controlling influences on effective risk identification and assessment for construction design management. Int J Project Manag. 2001;19(3):147–60. https://doi.org/10.1016/S0263-7863(99)00070-8 .

Wang S, Dulaimi M, Aguria M. Risk management framework for construction projects in developing countries. Constr Manag Econ. 2004;22(3):237–52. https://doi.org/10.1080/0144619032000124689 .

Travelers.com. 2019. https://www.travelers.com/iw-documents/business-insurance/tech-3D-whitepaper-BTCWH.0003D.pdf . Accessed 2 Feb 2019.

Sköld G, Vidarsson H. Analyzing the potentials of 3D-printing in the construction industry. A thesis in supply chain management (master’s thesis). Chalmers University of Technology, Gothenburg, Sweden, 2015.

Bak D. Rapid prototyping or rapid production? 3D printing processes move industry towards the latter. Assem Autom. 2003;23(4):340–5. https://doi.org/10.1108/01445150310501190 .

Zeltmann S, Gupta N, Tsoutsos N, Maniatakos M, Rajendran J, Karri R. Manufacturing and security challenges in 3D printing. JOM. 2016;68(7):1872–81. https://doi.org/10.1007/s11837-016-1937-7 .

Panda B, Paul SC, Tan MJ. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater Lett. 2017;209:146–9. https://doi.org/10.1016/j.matlet.2017.07.123 .

Workplace health and safety Queensland. Guide to machinery and equipment safety. 2015. https://www.worksafe.qld.gov.au/__data/assets/pdf_file/0010/82783/guidetomachinery-equipmentsafety.pdf . Accessed 15 Dec 2019.

Sweis G, Sweis R, Abuhammad A, Shboul A. Delays in construction projects: the case of Jordan. Int J Project Manag. 2008;26(6):665–74. https://doi.org/10.1016/j.ijproman.2007.09.009 .

Ling F, Hoi L. Risks faced by Singapore firms when undertaking construction projects in India. Int J Project Manag. 2006;24(3):261–70. https://doi.org/10.1016/j.ijproman.2005.11.003 .

Zou P, Zhang G, Wang J. Understanding the key risks in construction projects in China. Int J Project Manag. 2007;25(6):601–14. https://doi.org/10.1016/j.ijproman.2007.03.001 .

El-Sayegh S, Mansour M. Risk assessment and allocation in highway construction projects in the UAE. J Manag Eng. 2015. https://doi.org/10.1061/(asce)me.1943-5479.0000365 .

Faridi A, El-Sayegh S. Significant factors causing delay in the UAE construction industry. Constr Manag Econ. 2006;24(11):1167–76. https://doi.org/10.1080/01446190600827033 .

Ghosh S, Jintanapakanont J. Identifying and assessing the critical risk factors in an underground rail project in Thailand: a factor analysis approach. Int J Project Manag. 2004;22(8):633–43. https://doi.org/10.1016/j.ijproman.2004.05.004 .

Doloi H, Sawhney A, Iyer K, Rentala S. Analysing factors affecting delays in Indian construction projects. Int J Project Manag. 2012;30(4):479–89. https://doi.org/10.1016/j.ijproman.2011.10.004 .

Al-Saleh Y, Taleb H. The integration of sustainability within value management practices: a study of experienced value managers in the GCC countries. Project Manag J. 2010;41(2):50–9. https://doi.org/10.1002/pmj.20147 .

Fang D, Li M, Fong PS, Shen L. Risks in Chinese construction market—contractors’ perspective. J Constr Eng Manag. 2004;130(6):853–61. https://doi.org/10.1061/(ASCE)0733-9364(2004)130:6(853) .

Zhi H. Risk management for overseas construction projects. Int J Project Manag. 1995;13(4):231–7. https://doi.org/10.1016/0263-7863(95)00015-I .

Download references

This work was supported in part by funding from the American University of Sharjah (Grant No. EFRG18-SCR-CEN-42).

Author information

Authors and affiliations.

Department of Civil Engineering, American University of Sharjah, Sharjah, UAE

S. El-Sayegh & S. Manjikian

Department of Mechanical Engineering, American University of Sharjah, Sharjah, UAE

L. Romdhane

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to S. El-Sayegh .

Additional information

Publisher’s note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Reprints and permissions

About this article

El-Sayegh, S., Romdhane, L. & Manjikian, S. A critical review of 3D printing in construction: benefits, challenges, and risks. Archiv.Civ.Mech.Eng 20 , 34 (2020). https://doi.org/10.1007/s43452-020-00038-w

Download citation

Received : 22 February 2020

Accepted : 03 March 2020

Published : 10 March 2020

DOI : https://doi.org/10.1007/s43452-020-00038-w

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- 3D printing in construction

- Smart construction

- Risk management

- Find a journal

- Publish with us

- Track your research

- Research repository

- Education Repository

- Cultural Heritage

3D Printing with Bioplastics

Gokhale, Sneha (TU Delft Industrial Design Engineering)

Tempelman, E. (mentor) Faludi, J.J. (graduation committee)

Delft University of Technology

Integrated Product Design

Additive Manufacturing (AM) is undergoing a radical evolution. AM businesses such as Ultimaker (UM) are speeding up industrial production through digital design and local manufacturing to enable industries to produce “what they need, where they need it, and when they need it” (“Ultimaker”, 2019), while also being cost-effective. AM is perceived as a key sustainable technology as it enables efficient design and is believed to make less waste (“AMFG”, 2020), thus putting Ultimaker in a position to offer sustainability enhancements for their clients’ manufacturing processes. One topic of debate for AM sustainability, and the topic of investigation for this thesis, is whether bioplastics are more sustainable than fossil-based plastics for Fused Depositon Modeling (FDM) 3D Printing. Although PLA, a commonly used FDM material, is bio-based, it was hitherto unclear how much using this material and other BBPs can reduce the ecological impact of the 3D printing (3DP) process. This investigation was conducted in three phases- First, gaining an understanding of the context through literature review, market analysis and expert interviews. Second, material tests conducted to compare energy use and material properties of 3DP filaments. Third, a synthesis of findings from the first two phases into a material guide and recommendations for reducing the environmental impact of 3DPrinting. Whereas polymers are classified as bio-based/fossil-based and biodegradable/non-biodegradable, the 3DP filament materials available in the market often contain additives, fillers, or other polymers which make them difficult to categorize in a single type (Rohringer, 2020). Hence, a variety of polymers were selected for conducting material studies- including 3 UM-standard filaments, and 5 new filaments. Both environmental and functional properties were studied. For environmental impacts, literature showed that across the different parts of the 3DP filament life cycle, electricity use of the printer is the biggest contributor to ecological impact (Faludi et al., 2015). This motivated the investigation of energy use of a UM printer while printing selected materials. For functionality, expert interviews highlighted tensile properties, dimensional accuracy, and ease of printing as the most important criteria in the material selection process- thus motivating comparison tests for the same. An energy use comparison test revealed that electricity use is mainly influenced by build plate heating. More research is recommended to minimize build-plate heating for UM printers through solutions such as insulating the build chamber, or localized heating of build plate. The print quality and tensile tests affirm BIOPETG as a potential drop in replacement for UM-CPE. For both tests, new materials performed slightly worse, albeit often at acceptable levels, as compared to UM-standard materials. However, this can be attributed to the rudimentary level of print process optimization conducted for the new materials. Thus, it is recommended that these materials go through an elaborate optimization process in order to gain a more accurate impression of functional performance. As the final outcome of this investigation, the data collected was compiled into a material guide containing material properties and sustainability indicators. This visual can be referred by end-users like engineers, designers and production professionals to make appropriate material choices for their applications.

3D Printing Bioplastics Sustainability Materials FDM printing Ultimaker

http://resolver.tudelft.nl/uuid:f5d3bfa8-a550-4603-a591-32202d1f48df

Student theses

master thesis

© 2020 Sneha Gokhale

University of California Thesis: Reviewing 3D Printing in Construction, Including Mars

Share this Article

Andrew Truong recently presented a thesis, ‘ State-of-the-Art Review on 3D Printing Technology Applications in Construction ,’ to the University of California , Irvine. Reviewing 3D printing in construction, Truong tackles a multi-faceted topic regarding materials, technique, and the future of the industry—even going as far as discussing the potential for construction on Mars.

Today industrial users may be experimenting with new modes of production , different composites , or working on a larger scale with concrete, but while so many benefits are available, challenges still remain too. This leaves researchers a lot of room for discussion and experimentation, and especially as new projects with different requirements arise.

Truong takes his readers on a short foray through the history and emergence of 3D printing in the mainstream, noting especially its impacts on applications within medicine, the emergence of RepRap Open Source and Makerbot , and the growing popularity of FDM 3D printing overall. With the opportunity for making big headlines, numerous companies have built homes, touting record speed, and huge potential for economic residences in the future.

The first version of RepRap design (Mendel) [Source: https://reprap.org/wiki/Build_A_RepRap]

“In the construction industry, 3D printing is used to manufacture structures with nearly zero waste, minimum costs, and faster building time. Within days, depending on the complexity and size of building, a new structure can be built that can be customized for each building iteration,” explains Truong. “Houses built using 3D printing technology can be achieved by a variety of ways and each method of construction has its advantage and disadvantages.”

3D concrete printer in operation. No-slump concrete leaves the nozzle as a relatively stiff continuous filament. [23]

3DCP facility at the TU Eindhoven, with some examples of printed objects [23]

“The high resolution of the printing makes it able to print thin layers that are refined to have a finish exterior on the print. This nozzle houses the extrusion screw auger motor that pumps out the concrete before it is place on the 3D print,” states Truong. “The printer then moves in the direction and orientation of the printer to accurately 3D print the object. Therefore, the extrusion system has two motors. One motor is used to dispense the concrete out of the nozzle. The other motor is used to orient the nozzle in the correct direction. The shape of this nozzle creates a fine layer instead of a glob bead. The fine layer creates way for the 3D printer to have fine resolution prints in the same way a thermoplastic 3D printer works with a different print material and nozzle extruder.”

Printer head and nozzle. [23]

- Thermoplastics

- Photopolymers

The use of formworks in construction can lead to longer time in production, more waste of materials, and greater expense; with more streamlined techniques avoiding the need for frameworks, industrial users experience more latitude in design and actual ‘building.’ In constructing homes, no formworks are required.

“Doors and windows are built by placing a beam across the overhead gap while 3D printing or modular piece by piece construction is used,” said Truong. “After the house walls are 3D printed, the roof is then built to complete the structure. Mechanical, electrical, and plumbing can then be surface mounted to the structure. The exterior design of the house can be a layering pattern due to 3D printing or finish grout can be applied to create a smooth surface indistinguishable from traditional concrete building methods.”

Equipment can be and is routinely modified by engineers developing projects for different applications.

CyBe® Robotic Arm [38]

Apis Cor Crane Printer. [40]

WASP 3D Printed Geo House [41]

“Since Mars is covered with a regolith that can be used for in-situ construction, building on Mars is also economically feasible. 3D printing is an emerging field in construction that builds concrete formwork layer by layer without the use of molds nor forms. The feedstock used in 3D printing concrete requires a mix design that uses fine particles, because the feedstock must have a viscosity and workability that is able to flow through an extrusion and dynamic pump system,” states Truong. “The concrete mix will be 3D printable based on buildable layers, flowability through the system, and low gravitational out gassing [55]. The material properties of the mix design should also be structural enough to be used as radiation shielding and resilient to brittle cracking which induces a loss of cabin pressure in order be used in the Martian environment.”

The author goes into numerous designs created for Mars habitat challenges, yielding extremely interesting results.

Team AI. SpaceFactory of New York is the second-place winner in NASA’s 3D-Printed Habitat Challenge, Phase 3: Level 1 competition. [49]

Team Kahn-Yates from Jackson, Mississippi, won third place in Phase 3: Level 1 of NASA’s 3D-Printed Habitat Challenge. The team virtually designed a Mars habitat specifically suited to withstand dust storms and harsh climates on the red planet. [50]

“Research and development into the range of applications of 3D printing in construction is the beginning of a new building industry standard. The development of multistory construction will further increase market viability. While automated reinforcement, mechanical, electrical, and plumbing will increase construction speed and architectural design. The development of 3D printing thermoplastics with timber composites will make 3D printed houses competitive with suburban houses because homeowners will be able to hang picture frames and cabinets without anchoring into concrete,” concluded the author. “Prices for timber 3D printing filament is like 3D printing thermoplastics, because of the lack of an industrialized method of manufacturing the timber filament. Since the filaments are 77 made of sawdust, the filament should be able to be manufactured at a lower price. Several develops in the 3D printing construction industry will lead to the ubiquity of 3D printing construction and infrastructural changes in construction will provide an efficient method of building.”

What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com .

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

- Enter your email address *

- Comments This field is for validation purposes and should be left unchanged.

Recent News

InfinitForm Comes out of Stealth with AI Co-pilot for Manufacturing Design

US Army Contracts 3YOURMIND & Phillips Corp. for 3D Printed Tank Parts Identification

3D Printed Art

3D Printed Food

3D Printed Guns

You May Also Like

Printing money episode 18: the dc fly-in with mark burnham, addmfgcoalition.

It’s only been a week since the previous show, but Printing Money is back already with Episode 18. Certain events call for Printing Money’s coverage, and the recent 2nd Annual...

Aerospace OEM Invests $9.1M in Michigan for Metal 3D Printing and More

Barron Industries, a foundry based in Michigan specializing in serving the aerospace and defense sectors, has made a $9.1 million capital investment to expand its operations in Oxford, Michigan. The...

Can Higher Power Density Engines Lead to Broader 3D Printing Use?

Traditionally, when it comes to sports cars, interest has centered around metrics such as horsepower per cubic inch and power-to-weight ratios. These metrics are calculated and interpreted differently by various...

Wisconsin’s Evology Adds Digital Sheet Forming to Service Roster

Evology, a service bureau based in Wisconsin and specializing in serving strategic sectors like aerospace and defense, has added digital sheet forming (DSF) to its repertoire of manufacturing capabilities. Evology...

Print Services

Upload your 3D Models and get them printed quickly and efficiently.

- 3DPrinting Business Directory

Site Sponsor

Additive Manufacturing Strategies

Networking & Intelligence Summit, February 4-6, 2025

3D Printing jobs around the world.

- I would like to also register for free and access proprietary industry data from SmarTech and 3DPrint.com

- Email This field is for validation purposes and should be left unchanged.

3D Printing Guides

- Desktop 3D Printer Buyer’s Guide

- 3D Scanner Buyer's Guide

- Metal 3D Printer Guide

- Industrial Polymer 3D Printer Guide

- The 3D Systems Zone

- The HP Zone

- Desktop Metal Zone

- Bioprinting Zone

- The Space Zone

- 3D Printing Stocks Zone

Register to view and download proprietary industry data from AM Research and 3DPrint.com Questions? Contact [email protected]

Already have an account?

- First name *

- Last name *

- Password * Enter Password Confirm Password

- I agree to receive the 3DPrint.com Daily newsletter and promotional email correspondence.

85 3D Printing Essay Topic Ideas & Examples

🏆 best 3d printing topic ideas & essay examples, ⭐ most interesting 3d printing topics to write about.

- 💡 Good Essay Topics on 3D Printings

❓3D Printing Research Questions

- 3D Printing Industry and Market One can understand the industry of 3D technologies in terms of the software technology, the hardware and the nature of the products.

- Cloning, 3D Printing, and Artificial Parts: Replacement Strategies The possibility to turn such cells into any other is the main advantage of the method. This is 3D printing, apparently; as mentioned, it continues to grow more popular in medicine, which calls for studying […]

- 3D Printing in the Medical Field The key issue in the field of bioprinting remains the areas of application in medicine and the establishment of certain boundaries for this technology.

- 3D Printing Development for Fashion Industry The fashion industry was not moved or altered by 3D printing during the earlier days because most of the inventions covered the need to modify and improve the printing capability.

- UAE Government Foresight and Scenarios Program: The 3D Concrete Printing The 3D concrete printing initiative is the future of modernised, affordable, durable, and efficient means of construction for government projects across the UAE.

- 3D Printed Food and Utensils Safety The former is typically implemented in the production of simple foods and components, whereas the latter is used in combined culinary, with the implementation of both natural and printed ingredients.

- 3D Printing Technology in Medicine Notably, doctors need to learn how to use the printer in developing organs for patients in need of them. Employees need to be trained on how to use it at the workplace.

- 3D Heart Printing and Its Future Lee and Dai attributed the probability of the success of 3D technology to the materials used since they support the cellular components during and after bioprinting procedures.

- 3D Printer Elements and Features The objects that can be created with this printer should be at least 5x5x5 inches. These are some of the details that should be considered by the seller.

- Technology and Business: 3D Printer Impact This paper outlines the technology used for a Form 1 3D printer, as well as the impact this technology has had on business over the past ten years, the future of technology and business, the […]

- 3D Bioprinting of Physical Organs This sort of technology can be compared to the current prostatic usage and it has proven to be extremely beneficial for people.

- 3D Printing Industry in the UK Moreover, this research related the background of Makism 3D Corporation and the future of the 3D industry in the United Kingdom.

- Process Description: 3D Printing The material is the string-like strand of plastic coiled in the back of the printer. In turn, the movement of the print head is directed by the 3D file sent to the printer.

- 3D Bioprinting of Brown Adipose Tissue

- Additive Manufacturing: 3D Printing and the Future of Organizational Design

- Charting the Environmental Dimensions of Additive Manufacturing and 3D Printing

- 3D Printing and the Future of Nursing Education

- Current Applications and Future Perspectives of the Use of 3D Printing

- Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing

- 3D Printing and Its Effects on the World of Manufacturing

- Innovation Ecosystems Across Science, Technology, and Business: 3D Printing in China

- Financial and Funding Plan for a Biotech 3D Printing Company

- 3D Printing Food: Fiction or Reality?

- History, Future, and Applications of 3D Printing

- Limitations and Common Issues With 3D Printing

- Making Rare Materials Hands-On: 3D Printing a Possibility for Rare Materials

- Moral and Ethical Implications of 3D Printing Technology

- Nanoparticle Exposure During Processes Related to a Metal Object 3D Printing

- New Industrial Platforms and Radical Technology Foresight: 3D Printing in Europe

- 3D Printing Materials: Status, Opportunities, Market Forecasts

- Professional Skills for Information Technology for 3D Printing

- Reviewing Gun Control and 3D Printing in America

- Strategic Marketing Recommendation for the Launch of a 3D Printing Machine

💡 Good Essay Topics on 3D Printing

- Successful Business Models for 3D Printing Companies

- The Challenges and Boundaries of 3D Printing

- Overview of the Current Medical Uses of 3D Printing

- The Development and Challenge of 3D Printing

- The Different Areas and Applications of 3D Printing

- The Relationship Between Medical and Dental Industry and 3D Printing

- Biomimetic Scaffolds for Tissue Engineering: 3D Printing Techniques in Regenerative Medicine

- Tripolyphosphate-Crosslinked Chitosan & Gelatin Biocomposite Ink for 3D Printing of Uniaxial Scaffolds

- Understanding the Main Uses of 3D Printing

- The Potential Uses of 3D Printing Technology in the Modern World

- The Positive Impact of 3D Printing on Our Health and the Environment

- Why 3D Printing Service Bureaus Need to Be Automated

- The Effect of Three-Dimensional Printing on Prosthetic Limbs

- 3D Printing: Yesterday, Today, and Tomorrow

- The Link Between 3D Printing and Bioprinting Revolutionizing Healthcare

- 3D Printing Usage to Boost Competitive Advantage of American Manufacturing

- Technology and Ecology: Inventions With 3D Printer That Will Surprise You

- Development of Direct Metal Laser Sintering Machine

- 3D Printing and Its Effects on the Economy

- Digital Printing and Its Impact on the 3D Printing Future Growth

- What Are the Positive and Negative Impacts of 3D Printing?

- How Does 3D Printing Help Society?

- Can 3D Printing Make Everything?

- What Are the Potential Uses of 3D Printing?

- Is 3D Printing Used in Business Today?

- What Could 3D Printing Be Used for in the Future?

- Does 3D Printing Use Artificial Intelligence?

- How Does 3D Printing Affect the Modern Industry?

- Who Will Benefit the Most From 3D Printing?

- How Is 3D Printing Changing the World?

- Is 3D Printing Technology Improving?

- What Problems Can 3D Printing Solve?

- Is 3D Printing the Future of Sustainable Manufacturing?

- Does 3D Printing Save Energy?

- Will 3D Printing Change the World?

- How Can 3D Printing Help the Environment?

- What Is the Use of 3D Printing in Modern Technology?

- Can 3D Printing Help the Economy?

- How Is 3D Printing Used in Medicine?

- Is 3D Printing the Future of Fashion?

- Where Is 3D Printing Used in Industry?

- How Is 3D Printing Advancing the World We Live In?

- Which Industries Use 3D Printing Most?

- Can 3D Printing Help Developing Countries?

- What Is the Future Growth of 3D Printing?

- Is 3D Printing Good for the Environment?

- What Products Are Made Using 3D Printing?

- Does the Aerospace Industry Use 3D Printing Services?

- Why Is 3D Printing Important for the Future?

- Can 3D Printing Be Used for Architecture?

- Digital Transformation Topics

- Contemporary Art Questions

- Robots Questions

- Pop Art Titles

- Tattoo Research Ideas

- Cyberspace Topics

- Data Mining Titles

- Plastic Surgery Essay Titles

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2023, September 26). 85 3D Printing Essay Topic Ideas & Examples. https://ivypanda.com/essays/topic/3d-printing-essay-topics/

"85 3D Printing Essay Topic Ideas & Examples." IvyPanda , 26 Sept. 2023, ivypanda.com/essays/topic/3d-printing-essay-topics/.

IvyPanda . (2023) '85 3D Printing Essay Topic Ideas & Examples'. 26 September.

IvyPanda . 2023. "85 3D Printing Essay Topic Ideas & Examples." September 26, 2023. https://ivypanda.com/essays/topic/3d-printing-essay-topics/.

1. IvyPanda . "85 3D Printing Essay Topic Ideas & Examples." September 26, 2023. https://ivypanda.com/essays/topic/3d-printing-essay-topics/.

Bibliography

IvyPanda . "85 3D Printing Essay Topic Ideas & Examples." September 26, 2023. https://ivypanda.com/essays/topic/3d-printing-essay-topics/.

Dissertation - 3D Printing

3D Printing The New Industrial Revolution

Creative fields.

Graphic Design

- 3d printing

- Dissertation

- manufacturing

Attribution, Non-commercial, Share Alike

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

STUDY, DESIGN AND FABRICATION OF A 3D PRINTER A THESIS SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF BACHELOR OF TECHNOLOGY IN MECHANICAL ENGINEERING

Related Papers

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

IJRASET Publication

3D printing is called as desktop fabrication. It is a process of prototyping where by a structure is synthesized from a 3d model. The 3d model is stored in as a STL format and then forwarded to a 3D printer. It can use a good range of materials like ABS, PLA, and composites also .3D printing may be a rapidly developing and price optimized sort of rapid prototyping. The 3D printer prints the CAD design layer by layer forming a true object. 3D printing springs from inkjet desktop printers during which multiple deposit jets and therefore the printing material, layer by layer derived from the CAD 3D data. 3D printing significantly challenges production processes within the future. This type of printing is predicted to influence industries, like automotive, medical, education, equipment, consumer products industries and various businesses.

Alaa Jabbar Qasim ALmaliki

IAEME PUBLICATION

IAEME Publication

Now a day, the 3D printing is an increasingly commercially used technology. A crucial section of 3D printing is for providing the printer with printable content if possible, which is achieved by using reels of plastic filament, the most common is PLA, but it is the final product which is sold separately. For this situation, the other option arises that plastic material can be recycled and reused through bottles which are disposable which were discarded in order to be used as printable material. 3D Printing Technology is also defined as rapid prototyping, where a 3-dimensional structure is formed by laying the specific material layers. Three phases such as design, printing & finishing are included here in this process. They use any CAD software in the first step to create 3d design. Use this template to build an object in the 2nd stage 3D printer. And the finished item of the third step is extracted from the printer. This technology saves time and money. This avoids material waste. It is very useful to give the demo of any product in industries.

Mrudula Kulkarni

The purpose of this venture, or study, was to design and manufacture a 3-D printing machine while placing an emphasis on making the printer very cheap and maintaining high accuracy at the same time. Additive manufacturing machines that are currently available on the market that feature a large build volume complemented by high accuracy of the finished product cost on average approximately Rs. 40,00070,000 (700-1200 USD). The challenge confronted by this study was to overcome this price point by building a printer that maintained high accuracy and built volume while being as cheap as possible to manufacture. Therefore, the parameters that were set for this project were a budget of approximately Rs. 25,000 (380 USD) in order to manufacture a machine that provided a built volume of 25 x 25 x 20 cm. The machine also had to provide a high accuracy of finish and the baseline for accuracy was set at 100 microns..

Cephas Mawere

3D printing also known as Additive manufacturing technology has been dubbed the next big thing and be as equally wide spread as cellular telephone industry. 3D printers print objects from a digital template to a physical 3-dimensional physical object. The printing is done layer by layer (Additive manufacturing) using plastic, metal, nylon, and over a hundred other materials. 3D printing has been found to be useful in sectors such as manufacturing, industrial design, jewellery, footwear, architecture, engineering and construction, automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, and many others. It has been found to be a fast and cost effective solution in whichever field of use. The applications of 3D printing are ever increasing and it’s proving to be a very exciting technology to look out for. In this paper we seek to explore how it works and the current and future applications of 3D printing.

International Journal IJRITCC

Printing is a process for reproducing text and images, typically with ink on paper using a print press.3D printing is method of converting a virtual 3D model into a physical object from a digital file. It is achieved using Additive Process, where an object is created by laying down successive layers of material until the entire object is created.3D printing could revolutionize and reshape the world. Advances in 3D printing technology can significantly change and improve the manufacturing world with effects on energy use, waste reduction, customization, product availability, medicine, art, construction and science. By using this technology it becomes easier to transmit designs for new objects around the world

International Journal of Innovative Research in Science, Engineering and Technology (IJIRSET)

Nandkishor Dhawale

Co-Founder, Autosustaintive 3D printing and prototyping services, Vishrambagh, Sangli, India 3 Technical Consultant, Autosustaintive 3D printing and prototyping services, Vishrambagh, Sangli, India 4 ABSTRACT:-3D printing is an additive manufacturing process in which the entire part of a product is constructed using layer by layer deposition of materials that based on plastic and its derivatives. There are various processes of 3D printing namely fused deposition modelling (FDM), selective laser sintering (SLS), stereolithography (SLA), digital light processing (DLP), and multi jet fusion (MJF) to name a few. Each process has its unique characteristics and applications but the fused deposition modelling process is widely used due to its simplicity. As additive manufacturing processes becoming more common coupled with rapid technological advancement in the manufacturing sector, we may see the decentralised manufacturing network in the near future. The prices of 3D printers vary depending of several factors related to the type of printing material used, and the precision and quality requirements. This paper discusses a study conducted on using low cost 3d printer for rapid prototyping a commercially ready product. It also summarises the experiences, advantages and disadvantages of the study.

United International Journal for Research & Technology

UIJRT | United International Journal for Research & Technology

In this paper, we have talked about the technological development related to 3D printing. In which we have explained how 3D printing works and how it will affect our lives in the future. As we all know that 3D printing is going to be involved gradually in our everyday life. Therefore, we must bring new ideas about 3D printing for the benefit of society. As seen, 3D printing makes many of our tasks much easier, and we will be able to use it on a smaller scale, even in our homes in future. As we all know that there are always some flaws in technology in the initial stages. However, we are always on the path of making those techniques best by removing those imperfections. If seen, 3D printing is not a new technology, work has been going on for many years. However, the way we are now seeing the possibility. From this it seems that in future it will be used much more. In the coming time, most everyday items will be able to be made according to their requirement in a short time with the help of 3D printing. This will be a technique and a new way of advancement in technology.

International Research Journal of Multidisciplinary Scope

Hasan Nazha

International Journal of Engineering Research and Technology (IJERT)

IJERT Journal

https://www.ijert.org/a-review-on-3d-printer-a-new-technology https://www.ijert.org/research/a-review-on-3d-printer-a-new-technology-IJERTCONV6IS15016.pdf 3d Printing is also called additive manufacturing is simply a process of adding layers upon one another, in a desired manner to print three dimensional solid figures from CAD designs. 3d printing would be manufacturing without any boundaries. Prototyping which would take up to weeks in the old days can be done in a matter of hours using 3d printing. The innovators today are only limited by their imagination. anything they can think of can be printed irrespective of the complexity of the shape.3d printing offers freedom to create.

An easy pill to swallow -- new 3D printing research paves way for personalized medication

A new technique for 3D printing medication has enabled the printing of multiple drugs in a single tablet, paving the way for personalised pills that can deliver timed doses.

Researchers from the University of Nottingham's, Centre for Additive Manufacturing have led research alongside the School of Pharmacy that has fabricated personalised medicine using Multi-Material InkJet 3D Printing (MM-IJ3DP). The research has been published in Materials Today Advances.

The team have developed a cutting-edge method that enables the fabrication of customised pharmaceutical tablets with tailored drug release profiles, ensuring more precise and effective treatment options for patients.

Using Multi-Material InkJet 3D Printing (MM-IJ3DP), tablets can be printed that release drugs at a controlled rate, determined by the tablet's design. This is made possible by a novel ink formulation based on molecules that are sensitive to ultraviolet light. When printed, these molecules form a water-soluble structure.

The drug release rate is controlled by the unique interior structure of the tablet, allowing for timing the dosage release. This method can print multiple drugs in a single tablet, allowing for complex medication regimens to be simplified into a single dose.

Dr Yinfeng He, Assistant Professor in the Faculty of Engineering's Centre for Additive Manufacturing led the research, he said: "This is an exciting step forwards in the development of personalised medication. This breakthrough not only highlights the potential of 3D printing in revolutionizing drug delivery but also opens up new avenues for the development of next-generation personalized medicines."

"While promising, the technology faces challenges, including the need for more formulations that support a wider range of materials. The ongoing research aims to refine these aspects, enhancing the feasibility of MM-IJ3DP for widespread application." Professor Ricky Wildman added.

This technology will be particularly beneficial in creating medication that needs to release drugs at specific times, making it ideal for treating diseases, where timing and dosage accuracy are crucial. The ability to print 56 pills in a single batch demonstrates the scalability of this technology, providing a strong potential for the production of personalised medicines.

Professor Felicity Rose at the University of Nottingham's School of Pharmacy was one of the co-authors on the research, she says: "The future of prescribed medication lies in a personalised approach, and we know that up 50% of people in the UK alone don't take their medicines correctly and this has an impact on poorer health outcomes with conditions not being controlled or properly treated. A single pill approach would simplify taking multiple medications at different times and this research is an exciting step towards that."

- 3-D Printing

- Materials Science

- Engineering

- Educational Technology

- Computer Modeling

- Mobile Computing

- Mathematics

- Security engineering

- 3D computer graphics

- Photography

- Earth science

- Resonance (chemistry)

- Radiocarbon dating

Story Source:

Materials provided by University of Nottingham . Note: Content may be edited for style and length.

Journal Reference :

- Geoffrey Rivers, Anna Lion, Nur Rofiqoh Eviana Putri, Graham A. Rance, Cara Moloney, Vincenzo Taresco, Valentina Cuzzucoli Crucitti, Hannah Constantin, Maria Inês Evangelista Barreiros, Laura Ruiz Cantu, Christopher J. Tuck, Felicity R.A.J. Rose, Richard J.M. Hague, Clive J. Roberts, Lyudmila Turyanska, Ricky D. Wildman, Yinfeng He. Enabling high-fidelity personalised pharmaceutical tablets through multimaterial inkjet 3D printing with a water-soluble excipient . Materials Today Advances , 2024; 22: 100493 DOI: 10.1016/j.mtadv.2024.100493

Cite This Page :

Explore More

- Stopping Flu Before It Takes Hold

- Cosmic Rays Illuminate the Past

- Star Suddenly Vanish from the Night Sky

- Dinosaur Feather Evolution

- Warming Climate: Flash Droughts Worldwide

- Record Low Antarctic Sea Ice: Climate Change

- Brain 'Assembloids' Mimic Blood-Brain Barrier

- 'Doomsday' Glacier: Catastrophic Melting

- Blueprints of Self-Assembly

- Meerkat Chit-Chat

Trending Topics

Strange & offbeat.

- Press Enter to activate screen reader mode.

ETH students develop drones, robots and vehicles

- Mechanical engineering

Racing cars, robots, aircraft: Bachelor’s students in the Department of Mechanical and Process Engineering spend two semesters working on a project in teams. They will be presenting their results on 28 May 2024.

- mode_comment Number of comments

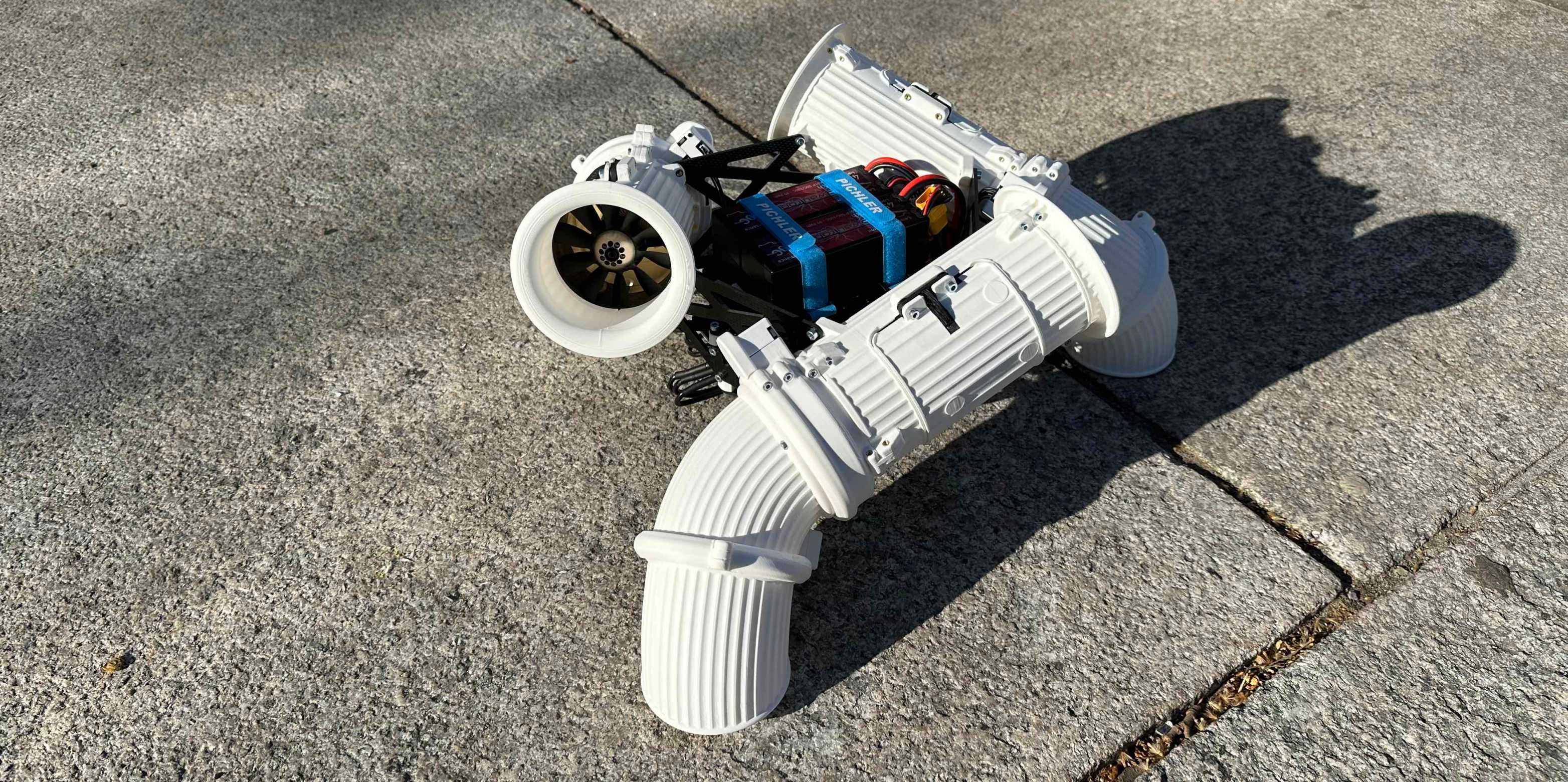

Ten teams have spent a year developing prototypes that demonstrate the current state of the art in the areas of additive manufacturing, robotics, and drive and transport technologies. The Focus projects are an integral part of a Bachelor’s degree in mechanical and process engineering. The students complete the entire process independently – from the project idea and design studies through to the search for sponsors and production. These are the projects they have realised this year:

AVERO – the safe inspection drone

Drone propellers pose a risk: people can injure themselves on their rotating blades, and objects or the drone itself can be damaged in the event of collisions. The eleven-strong team of the AVERO Focus project consequently undertook to move the propellers to the drone’s interior, placing the propellers in tubes while using pivoted nozzles to control the air current generated.

The innovative propulsion offers further advantages: the drone can rotate in any position around two axles more than conventional models and fly closely alongside objects. Possible fields of deployment are inspections of infrastructures that are difficult to access and in busy environments such as building sites.

RAPTURE – 3D printing for multi-material rocket parts

Additive manufacturing involves creating components layer by layer. One of these 3D printing processes is the repeated application and selective fusing of metal powder with a laser. This technique enables the construction of components with particularly fine and complex geometries. In the RAPTURE Focus project, students developed a new machine architecture that enables them to manufacture parts from two different metals. To this end, they are working on a particularly fast and material-saving technique that can be deployed in aerospace and many other sectors. The students aim to use this technique to make special components such as nozzles and other engine components with customised material properties. The technology promises to enhance the cost efficiency and performance of rocket systems.

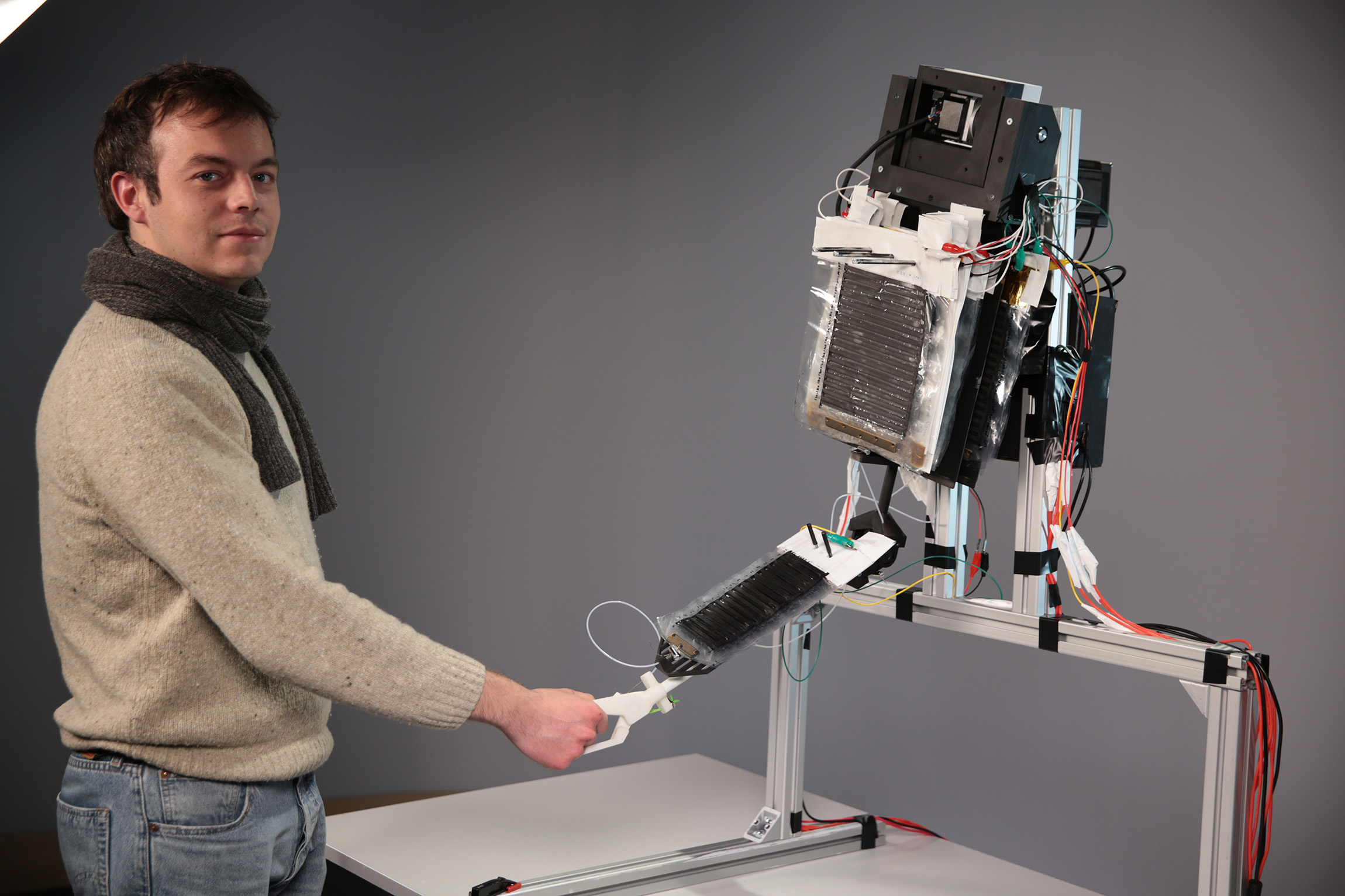

SARA – Soft Actuated Robotic Arm

Despite major progress, upper-limb prostheses are still frequently perceived as being too heavy. The SARA Focus project therefore aims to construct a lightweight and flexible robotic arm that can be further developed into a prosthesis. The vision of the students in the project team is for users of prostheses to be barely aware of their disadvantages in the future.

With the development of the robotic arm, they plan to pave the way for a new generation of lightweight, agile and silent prostheses. Instead of conventional actuators, the students are making use of a new robotics technology that copies how human muscles work. The actuators – in other words, the elements that generate movement – consist of liquids in thin plastic films that convert electrical into mechanical energy. By integrating artificial muscles into the arm prosthesis, the students aim to make the latter more agile and at the same time more lightweight.

Other Focus projects in 2023/24

- external page aCentauri call_made is constructing an aerodynamic racing car powered exclusively by solar cells and capable of reaching motorway speeds. The team will be entering the World Solar Challenge, which covers 3,000 km in the Australian outback, for the second time in the autumn of 2025.

- external page aidara call_made is developing a robot assistant known as a “cobot” that is capable of understanding tasks and identifying objects independently thanks to AI-based speech and image recognition algorithms. The robotic arm serves as a “third hand” and hands over objects on request.

- external page Cellsius Project H2 call_made is developing a hydrogen powertrain for a light aircraft. The two-seater aircraft is to be emission-free, quiet and economical and offer an environmentally friendly alternative for training and leisure flights.

- external page Formula Student Electric call_made is pursuing the goal of further boosting the performance of electric racing cars. The car is being assembled following a four-month development phase. The team is entering their prototype in the annual “Formula Student” contest.

- LEVA is constructing a robot that is capable of lifting and carrying boxes on its own and moves like a four-legged animal. It can be deployed in confined spaces and on uneven terrain and is intended to make work on building sites, in agriculture and intralogistics safer and more efficient.

- NOCTUA is developing a quiet long-range drone for the surveillance of wild animals in African wildlife reserves. Around 90 elephants and two rhinos fall victim to poachers there every day. The drone is designed to fly autonomously over large areas for up to 12 hours without disturbing the animals.

- external page Swissloop call_made is further developing its carbon-neutral high-speed transport system Hyperloop. It is taking part in the European Hyperloop Week, an international competitive event, with its new levitating pod in which goods and passengers are to be transported in future at speeds of up to 1,000 km/h.

Focus project rollout 2023/24

The students will be presenting their project results at a public exhibition: Tuesday, 28 May 2024, from 12 noon until 5.30 p.m. , LEE building, Leonhardstrasse 21, 8092 Zurich.

The teams will give talks on their projects at an event in the Main Building: Tuesday, 28 May 2024, from 2.00 p.m. until 3.45 p.m. , in the Audi Max, Main Building, F 30, Rämistrasse 101, 8092 Zurich.

Further information about the Focus Rollout

Newsletter subscription

Similar topics.

IMAGES

VIDEO

COMMENTS

3D printing (additive manufacturing) has been around for more than 30 years. A lot of technological progress has been made in that time, most recently with new innovations such as metal 3D printing. Although the technology seems to hold a lot of promise, the rate of adoption has not lived up to the hype. The aim of this thesis is to research ...

open access. 3D printing, unlike other manufacturing processes, being an additive process has emerged as a viable technology for the production of engineering components. The aspects associated with 3D printing such as less material wastage, ease of manufacturing, less human involvement, very less post processing and energy efficiency makes the ...

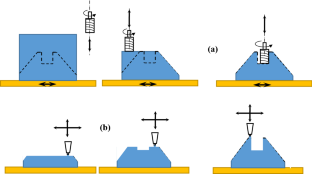

2.1 3D printing. 3D printing is defined as the process of making an object from a three-dimensional model by adding thin layers of material on top of each other [].Figure 1 presents a schematic that shows the difference between classical manufacturing (subtractive) and 3D printing or Additive Manufacturing (AM). AM is defined by the American Society for Testing and Materials (ASTM) and the ...

In the last few years, scattered experiences of the application of additive manufacturing in the construction of buildings using 3D printing with robots or automated equipment have emerged around the world. These use a variety of procedures and suggest relevant advantages for the construction industry. In order to identify the different processes and features in development in this field and ...

2 0 2 0 MASTER'S THESIS Title Exploring the Potential of 3D printing for Building Houses in Nigeria and Brief Numerical Analysis of Lintels in 3D Printed Houses July 2020 DOI: 10.13140/RG.2.2 ...

Research interest in three-dimensional (3D) printing has been greatly aroused since 1990 due to its outstanding merits, such as freedom of design, mass customization, waste minimization and fast prototyping complex structures. To formally elaborate the research status of the 3D printing field, a bibliometric analysis is applied to evaluate the related publications from 1990 to 2020 based on ...

3D printing technology. Keywords: 3D printing; multidisciplinary; bibliometric; additive manufacturing; Web of Science 1. Introduction 3D printing, also referred to as additive manufacturing (AM), is a set of layer-by-layer processes to form 3D objects with various structures and complex geometries directly from digital models [1].

Abstract. Completed a rewarding dissertation journey exploring 3D Design and Printing technology under the guidance of Prof. Amit Garg. Conducted in-depth research, software exploration, and ...

Your tasks: Test and optimize materials and processes for 3D-lithography. Fabrication photonic wirebonds on single-mode fibers or c) chips as a simple test interface for 3D-printing. Measure the surface quality, shape and performance of the fabricated structures with electron microscopy (SEM), atomic force microscopy (AFM), white-light vertical ...

Topic Information. Dear Colleagues, Additive manufacturing (AM), also known as 3D printing, is an innovative and emerging technology offering many advantages for various applications and industries at the design, material and processing level. AM offers many opportunities, encourages unique designs and integrates new materials, smart production ...

2.0 LITERATURE REVIEW. Quite simply, the term "3D printing" also known as "additive manufacturing". refers to the process of bu il ding products b y adding many ver y thin layers of ma ...

Also, this part contains the analysis of the workflow and various kinds of 3D printers. The outcome of the thesis deciding on the selection of construction 3D printing technology based the results of a comparative analysis of small-scale and large-scale construction 3D printing. 3D printer, additive manufacturing, construction, ceramics.

Currently, 3D printing primarily used for producing artificial heart pump [3], jewelry collections [4], 3D printed cornea [5], PGA rocket engine [6], steel bridge in Amsterdam [7] and other products related to the aviation industry as well as the food industry. 3D printing technology has originated from the layer by layer fabrication technology ...

One topic of debate for AM sustainability, and the topic of investigation for this thesis, is whether bioplastics are more sustainable than fossil-based plastics for Fused Depositon Modeling (FDM) 3D Printing. Although PLA, a commonly used FDM material, is bio-based, it was hitherto unclear how much using this material and other BBPs can reduce ...

Andrew Truong recently presented a thesis, 'State-of-the-Art Review on 3D Printing Technology Applications in Construction,' to the University of California, Irvine.Reviewing 3D printing in ...

Another significant advantage of 3D printing is that it leads to increased efficiency as nearly all raw material can be utilized in the manufacturing process. 3D Printing Industry in the UK. Moreover, this research related the background of Makism 3D Corporation and the future of the 3D industry in the United Kingdom.

Mainly the printing of concrete and cementitious materials has lately gained much interested in the field of architecture and construction. Unsurprisingly, varying techniques have been developed during the past years. An overview of different construction-scale 3D printing techniques is given by Lim et al. (2012).

A 6000 word count professional piece of written work answering the question "is 3D printing really the new industrial revolution?". The knowledge behind my work has been developed from repitable sources including books, journals, online articles and personal experiences of design professionals.

The effect of 3D printing on entrepreneurship. The aim of this section is to investigate how 3D printing technologies. can help overcome the challenges traditionally associated with entre ...

Nokia has displayed the 3D designs of their mobiles so that owners will be able to recreate their own phone case [5]. 1.5. PROCESS OF 3D PRINTING: 3D printing process can be described and defined in the following steps: CAD Model Creation: Initially, the item to be 3D printed is designed utilizing a ComputerAided Design (CAD) software.

1. Introduction to 3D Printing What is 3d Printing 3d Printing or Additive Manufacturing (AM) is a process of making 3 Dimensional objects from a Computer-aided design (CAD) model. As the name ...

Enabling high-fidelity personalised pharmaceutical tablets through multimaterial inkjet 3D printing with a water-soluble excipient. Materials Today Advances , 2024; 22: 100493 DOI: 10.1016/j.mtadv ...

Ostbayerische Technische Hochschule Regensburg. Ageing workforce in the context of modern manufacturing: robots, ergonomics, novel workspace designs, new ways of management and organization, etc ...

RAPTURE - 3D printing for multi-material rocket parts. Additive manufacturing involves creating components layer by layer. One of these 3D printing processes is the repeated application and selective fusing of metal powder with a laser. This technique enables the construction of components with particularly fine and complex geometries.