MIT Libraries home DSpace@MIT

- DSpace@MIT Home

- MIT Libraries

- Doctoral Theses

3D-printing form and function

Alternative title

Other contributors, terms of use, description, date issued, collections.

A critical review of 3D printing in construction: benefits, challenges, and risks

- Review Article

- Published: 10 March 2020

- Volume 20 , article number 34 , ( 2020 )

Cite this article

- S. El-Sayegh ORCID: orcid.org/0000-0002-9127-0318 1 ,

- L. Romdhane ORCID: orcid.org/0000-0001-8509-2386 2 &

- S. Manjikian 1

16k Accesses

119 Citations

Explore all metrics

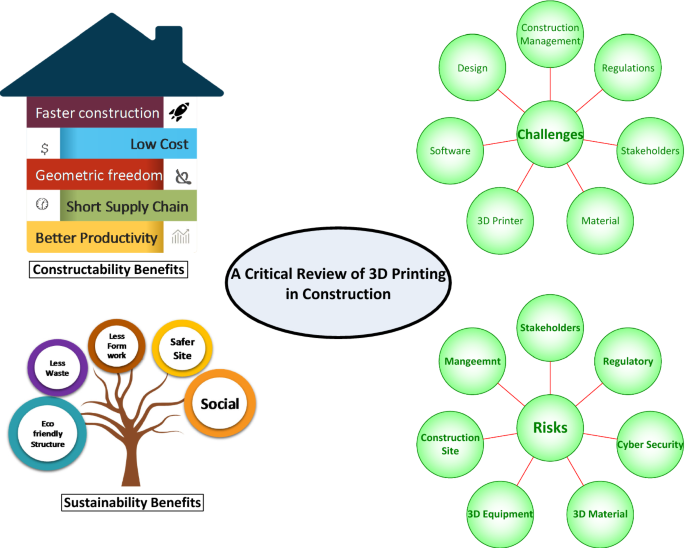

This paper provides a critical review of the related literature on 3D printing in construction. The paper discusses and evaluates the different 3D printing techniques in construction. The paper also discusses and categorizes the benefits, challenges, and risks of 3D printing in construction. The use of 3D printing technology offers several advantages over traditional methods. However, it comes with its own additional challenges and risks. The main benefits of 3D printing in construction include constructability and sustainability benefits. The challenges are categorized into seven groups. The main challenges, found through the literature, are material related. The most cited challenges are material printability, buildability, and open time. Additionally, scalability, structural integrity, and lack of codes and regulations are frequently cited as major challenges. The additional risks are categorized into seven groups: 3D printing material, 3D printing equipment, construction site, and environment, management, stakeholders, regulatory and economic, and cybersecurity risks. The paper fills a gap in the literature as it addresses a new aspect of 3D printing, which is risk. The paper also provides some insights, recommendations, and future research ideas.

Graphic abstract

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price excludes VAT (USA) Tax calculation will be finalised during checkout.

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

3D printing in construction: state of the art and applications

3D Printing for Construction: A Systematic Review of Its Sustainability

3D Printing in Construction Industry: A State of Art

Gerbert P, Castagnino S, Rothballer C, Renz A, Filitz R. The transformative power of building information modeling, March 08, 2016 Boston Consulting Group. 2016. https://www.bcgperspectives.com/content/articles/engineered-products-project-business-digital-engineering-construction/ . Accessed 28 Jan 2019.

Horvath J. Mastering 3D printing (technology in action). Berkeley: Apress; 2014. https://doi.org/10.1007/978-1-4842-0025-4 .

Book Google Scholar

Maskuriy R, Selamat A, Maresova P, Krejcar A, Olalekan David O. Industry 4.0 for the construction industry: review of management perspective. Economies. 2019;68(7):4. https://doi.org/10.3390/economies7030068 .

Article Google Scholar

Bock T. The future of construction automation: technological disruption and the upcoming ubiquity of robotics. Autom Constr. 2015;59:113–21. https://doi.org/10.1016/j.autcon.2015.07.022 .

García de Soto B, Agustí-Juan I, Hunhevicz J, Joss S, Graser K, Habert G, Adey B. Productivity of digital fabrication in construction: cost and time analysis of a robotically built wall. Autom Constr. 2018;92:297–311. https://doi.org/10.1016/j.autcon.2018.04.004 .

Brettel M, Friederichsen N, Keller M, Rosenberg M. How virtualization, decentralization and network building change the manufacturing landscape: an industry 4.0 perspective. Int J Mech Aerosp Ind Mechatron Manuf Eng. 2014;8(1):37–44.

Google Scholar

Oesterreich TD, Teuteberg F. Understanding the implications of digitisation and automation in the context of industry 4.0: a triangulation approach and elements of a research agenda for the construction industry. Comput Ind. 2016;83:121–39. https://doi.org/10.1016/j.compind.2016.09.006 .

Dallasegaa P, Raucha E, Linderb C. Industry 4.0 as an enabler of proximity for construction supply chains: a systematic literature review. Comput Ind. 2018;99:205–25. https://doi.org/10.1016/j.compind.2018.03.039 .

Alaloul WS, Liew MS, Zawawi NW, Mohammed BS. Industry revolution IR 4.0: future opportunities and challenges in construction industry. In: MATEC web of conferences 203, 2010. 2018. https://doi.org/10.1051/matecconf/201820302010 .

Hager I, Golonka A, Putanowicz R. 3D printing of buildings and building components as the future of sustainable construction? Procedia Eng. 2016;151:292–9. https://doi.org/10.1016/j.proeng.2016.07.357 .

Noorani R. 3D printing: technology, applications, and selection. Boca Raton: CRC Press; 2018.

Kietzmann J, Pitt L, Berthon P. Disruptions, decisions, and destinations: enter the age of 3D printing and additive manufacturing. Bus Horiz. 2015;58(2):209–15. https://doi.org/10.1016/j.bushor.2014.11.005 .

Davtalab O, Kazemian A, Khoshnevis B. Perspectives on a BIM-integrated software platform for robotic construction through contour crafting. Autom Constr. 2018;89:13–23. https://doi.org/10.1016/j.autcon.2018.01.006 .

Camacho D, Clayton P, O’Brien W, Seepersad C, Juenger M, Ferron R, Salamone S. Applications of additive manufacturing in the construction industry: a forward-looking review. Autom Constr. 2018;89:110–9. https://doi.org/10.1016/j.autcon.2017.12.031 .

Yossef M, Chen A. Applicability and limitations of 3D printing for civil structures. Civ Constr Environ Eng Conf Present Proc. 2015;35:87–99.

Lim S, Buswell RA, Le TT, Austin SA, Gibb AG, Thorpe T. Developments in construction-scale additive manufacturing processes. Autom Constr. 2011;21:262–8. https://doi.org/10.1016/j.autcon.2011.06.010 .

Wu P, Wang J, Wang X. A critical review of the use of 3D printing in the construction industry. Autom Constr. 2016;68:21–31. https://doi.org/10.1016/j.autcon.2016.04.005 .

PMBOK. A guide to the project management body of knowledge. 6th ed. Newtown Square: Project Management Institute Standards Committee, PMI; 2017.

Barber R. Understanding internally generated risks in projects. Int J Project Manag. 2005;23(8):584–90. https://doi.org/10.1016/j.ijproman.2005.05.006 .

ANDI. The importance and allocation of risks in Indonesian construction projects. Constr Manag Econ. 2006;24(1):69–80. https://doi.org/10.1080/01446190500310338 .

El-Sayegh S. Risk assessment and allocation in the UAE construction industry. Int J Project Manag. 2008;26(4):431–8. https://doi.org/10.1016/j.ijproman.2007.07.004 .

Jung K-Y, Roh M-S. A study for an appropriate risk management of new technology deployment in nuclear power plants. Ann Nucl Energy. 2016;99:157–64. https://doi.org/10.1016/j.anucene.2016.08.013 .

Conner BP, Manogharan GP, Meyers KL. An assessment of implementation of entry-level 3D printers from the perspective of small businesses. Rapid Prototyp J. 2015;21(5):582–97. https://doi.org/10.1108/RPJ-09-2014-0132 .

Malone D. 2017. https://www.bdcnetwork.com/europe%E2%80%99s-first-3d-printed-building-has-been-completed . Accessed 22 Feb 2019.

Paul S, Van Zijl G, Tan M, Gibson I. A review of 3D concrete printing systems and materials properties: current status and future research prospects. Rapid Prototyp J. 2018;24(4):784–98. https://doi.org/10.1108/RPJ-09-2016-0154 .

Ghaffar S, Corker J, Fan M. Additive manufacturing technology and its implementation in construction as an eco-innovative solution. Autom Constr. 2018;93:1–11. https://doi.org/10.1016/j.autcon.2018.05.005 .

Uppalla S, Tadikamalla M. A review on 3D printing of concrete—the future of sustainable construction. I-Manager’s J Civ Eng. 2017;7(3):49–62. https://doi.org/10.26634/jce.7.3.13610 .

Labonnote N, Rønnquist A, Manum B, Rüther P. Additive construction: state-of-the-art, challenges and opportunities. Autom Constr. 2016;72:347–66. https://doi.org/10.1016/j.autcon.2016.08.026 .

Bos F, Wolfs R, Ahmed Z, Salet T. Additive manufacturing of concrete in construction: potentials and challenges of 3D concrete printing. Virtual Phys Prototyp. 2016;11(3):209–25. https://doi.org/10.1080/17452759.2016.1209867 .

Tay YWD, Panda B, Paul SC, Noor Mohamed NA, Tan MJ, Leong KF. 3D printing trends in building and construction industry: a review. Virtual Phys Prototyp. 2017;12(3):261–76.

Shakor P, Nejadi S, Paul G, Malek S. Review of emerging additive manufacturing technologies in 3D printing of cementitious materials in the construction industry. Front Built Environ. 2019;4:85.

Hamidi F, Aslani F. Additive manufacturing of cementitious composites: materials, methods, potentials, and challenges. Constr Build Mater. 2019;218:582–609. https://doi.org/10.1016/j.conbuildmat.2019.05.140 .

ISO/ASTM52900-15. Standard terminology for additive manufacturing—general principles—terminology. West Conshohocken: ASTM International; 2015.

Gibson I, Rosen D, Stucker B. Additive manufacturing technologies: 3D printing, rapid prototyping, and direct digital manufacturing. 2nd ed. New York: Springer; 2015. https://doi.org/10.1007/978-1-4939-2113-3 .

D-shape.com. D-shape building process. 2019. https://d-shape.com/the-technology/d-shape-building-process/ . Accessed 7 Apr 2019.

Xu J, Ding L, Love P. Digital reproduction of historical building ornamental components: from 3D scanning to 3D printing. Autom Constr. 2017;76:85–96. https://doi.org/10.1016/j.autcon.2017.01.010 .

Yeon J, Kang J, Yan W. Spall damage repair using 3D printing technology. Autom Constr. 2018;89:266–74. https://doi.org/10.1016/j.autcon.2018.02.003 .

Mueller RP, Howe S, Kochmann D, Ali H, Andersen C, Burgoyne H, Chambers W, Clinton R, De Kestellier X, Ebelt K, Gerner S, Hofmann D, Hogstrom K, Ilves E, Jerves A, Keenan R, Keravala J, Khoshnevis B, Lim S, Metzger P, Meza L, Nakamura T, Nelson A, Partridge H, Pettit D, Pyle R, Reiners E, Shapiro A, Singer R, Tan W-L, Vazquez N, Wilcox B, Zelhofer A. Automated additive construction (AAC) for earth and space using in-situ resources. In: Proceedings of the fifteenth biennial ASCE aerospace division international conference on engineering, science, construction, and operations in challenging environments (Earth & Space 2016). Reston: American Society of Civil Engineers; 2016. http://oro.open.ac.uk/45865/1/3Dadditive_paper_final.pdf . Accessed 15 Dec 2019.

Ingaglio J, Fox J, Naito CJ, Bocchini P. Material characteristics of binder jet 3D printed hydrated CSA cement with the addition of fine aggregates. Constr Build Mater. 2019;206:494–503.

Shakor P, Sanjayan J, Nazari A, Nejadi S. Modified 3D printed powder to cement-based material and mechanical properties of cement scaffold used in 3D printing. Constr Build Mater. 2017;138:398–409.

Lowke D, Dini E, Perrot A, Weger D, Gehlen C, Dillenburger B. Particle-bed 3D printing in concrete construction: possibilities and challenges. Cem Concr Res. 2018;112:50–65. https://doi.org/10.1016/j.cemconres.2018.05.018 .

Khoshnevis B, Hwang D, Yao KT, Yeh Z. Mega-scale fabrication by contour crafting. Int J Ind Syst Eng. 2006;1(3):301–20. https://doi.org/10.1504/IJISE.2006.009791 .

Craveiro F, Bartolo H, Gale A, Duarte J, Bartolo P. A design tool for resource-efficient fabrication of 3D-graded structural building components using additive manufacturing. Autom Constr. 2017;82:75–83. https://doi.org/10.1016/j.autcon.2017.05.006 .

Duballet R, Baverel O, Dirrenberger J. Classification of building systems for concrete 3D printing. Autom Constr. 2017;83:247–58. https://doi.org/10.1016/j.autcon.2017.08.018 .

Gosselin C, Duballet R, Roux P, Gaudillière N, Dirrenberger J, Morel P. Large-scale 3D printing of ultra-high performance concrete: a new processing route for architects and builders. Mater Des. 2016;100:102–9. https://doi.org/10.1016/j.matdes.2016.03.097 .

Zareiyan B, Khoshnevis B. Effects of interlocking on interlayer adhesion and strength of structures in 3D printing of concrete. Autom Constr. 2017;83:212–21. https://doi.org/10.1016/j.autcon.2017.08.019 .

Apis Cor. We print buildings. http://www.apis-cor.com/en/ . Accessed 15 Dec 2019.

Zhang X, Li M, Lim J, Weng Y, Tay Y, Pham H, Pham Q. Large-scale 3D printing by a team of mobile robots. Autom Constr. 2018;95:98–106. https://doi.org/10.1016/j.autcon.2018.08.004 .

Barnett E, Gosselin C. Large-scale 3D printing with a cable-suspended robot. Addit Manuf. 2015;7:27–44. https://doi.org/10.1016/j.addma.2015.05.001 .

https://www.constructionweekonline.com/products-services/257548-video-cobod-set-to-ship-worlds-largest-3d-printer-to-saudi-arabia .

Kothman I, Faber N. How 3D printing technology changes the rules of the game. J Manuf Technol Manag. 2016;27(7):932–43. https://doi.org/10.1108/JMTM-01-2016-0010 .

Feng L, Yuhong L. Study on the status quo and problems of 3D printed buildings in China. Glob J Hum Soc Sci H Interdiscip. 2014;14(5):7–10.

3D Printers, WASP, Leading Company in the 3D printing industry. 2019. https://www.3dwasp.com/en/ . Accessed 15 Dec 2019.

Le T, Austin S, Lim S, Buswell R, Gibb A, Thorpe T. Mix design and fresh properties for high-performance printing concrete. Mater Struct. 2012;45(8):1221–32. https://doi.org/10.1617/s11527-012-9828-z .

Buswell RA, Leal de Silva WR, Jones SZ, Dirrenberger J. 3D printing using concrete extrusion: a roadmap for research. Cem Concr Res. 2018;112:37–49.

Cemex Ventures. Benefits of 3D printing in construction. 2019. https://www.cemexventures.com/benefits-of-3d-printing-in-construction/ . Accessed 19 Jan 2019.

Le T, Austin S, Lim S, Buswell R, Law R, Gibb A, Thorpe T. Hardened properties of high-performance printing concrete. Cem Concr Res. 2012;42(3):558–66. https://doi.org/10.1016/j.cemconres.2011.12.003 .

Papachristoforou M, Mitsopoulos V, Stefanidou M. Evaluation of workability parameters in 3D printing concrete. Procedia Struct Integr. 2018;10:155–62. https://doi.org/10.1016/j.prostr.2018.09.023 .

Wangler T, Lloret E, Reiter L, Hack N, Gramazio F, Kohler M, Flatt R. Digital concrete: opportunities and challenges. Rilem Tech Lett. 2016;1:67–75. https://doi.org/10.21809/rilemtechlett.2016.16 .

Hambach M, Volkmer D. Properties of 3D-printed fiber-reinforced portland cement paste. Cem Concr Compos. 2017;79:62–70. https://doi.org/10.1016/j.cemconcomp.2017.02.001 .

Doo-Yeol Y, Young-Soo Y. A review on structural behavior, design, and application of ultra-high-performance fiber-reinforced concrete. Int J Concr Struct Mater. 2016;10(2):125–42. https://doi.org/10.1007/s40069-016-0143-x .

Ducoulombier N, Chateau C, Bornert M, Caron J-F, Weitkamp T, Perrin J. Characterisation and modelling of interfacial damage in fibre reinforced concrete for 3D printing in construction. In: 10th international conference on fracture mechanics of concrete and concrete structures, June 2019, Bayonne, France. https://doi.org/10.21012/FC10.235562 .

Bos F, Bosco E, Salet T. Ductility of 3D printed concrete reinforced with short straight steel fibers. Virtual Phys Prototyp. 2019;14(2):160–74.

Feng P, Meng X, Zhang H. Mechanical behavior of FRP sheets reinforced 3D elements printed with cementitious materials. Compos Struct. 2015;134:331–42.

Arayici Y, Egbu CO, Coates SP. Building information modelling (BIM) implementation and remote construction projects: issues, challenges, and critiques. J Inf Technol Constr. 2012;17:75–92.

Robichaud L, Anantatmula VS. Greening project management practices for sustainable construction. J Manag Eng. 2011;27(1):48–57. https://doi.org/10.1061/(ASCE)ME.1943-5479.0000030 .

Feng P, Meng X, Chen J, Ye L. Mechanical properties of structures 3D printed with cementitious powders. Constr Build Mater. 2015;93:486–97. https://doi.org/10.1016/j.conbuildmat.2015.05.132 .

Zhang J, Hu Z. BIM- and 4D-based integrated solution of analysis and management for conflicts and structural safety problems during construction: 1. Principles and methodologies. Autom Constr. 2011;20(2):155–66. https://doi.org/10.1016/j.autcon.2010.09.013 .

World Economic Forum. Winsun: demonstrating the viability of 3D printing at the construction scale. 2016. https://futureofconstruction.org/case/winsun/ . Accessed 15 Dec 2019.

Dubai Future Foundation. Dubai 3D printing strategy. www.dubaifuture.gov.ae/our-initiatives/dubai-3d-printing-strategy/#1458229619399-0dfdadfa-8f328fc7-fbc6 . Accessed 1 Nov 2018.

D Printhuset. The construction of Europe’s first 3D Printed building has begun and is almost complete. 3D Printhuset. http://www.3dprinthuset.dk/europes-first-3d-printed-building/ . Accessed 1 Nov 2018.

CyBe. Redefining construction by enabling 3D concrete printing by providing hardware, software, material, education, certification and business development. CyBe Construction. http://www.cybe.eu/ . Accessed 1 Nov 2018.

CNN Style. The world’s longest 3D-printed concrete bridge is finished. 2019. https://edition.cnn.com/style/article/shanghai-3d-printed-bridge-scli-intl/index.html . Accessed 2 Feb 2019.

Buswell RA, Soar RC, Gibb AGF, Thorpe A. Freeform construction: mega-scale rapid manufacturing for construction. Autom Constr. 2007;16(2):224–31. https://doi.org/10.1016/j.autcon.2006.05.002 .

Campbell T, Williams C, Ivanova O, Garrett B. Could 3D printing change the world? Technologies, potential, and implications of additive manufacturing. Atlantic Council. 2011. http://www.atlanticcouncil.org/images/files/publication_pdfs/403/101711_ACUS_3DPrinting.PDF . Accessed 15 Dec 2019.

Khoshnevis B. Automated construction by contour crafting—related robotics and information technologies. Autom Constr. 2004;13(1):5–19. https://doi.org/10.1016/j.autcon.2003.08.012 .

Chen Q, García de Soto B, Adey B. Construction automation: research areas, industry concerns and suggestions for advancement. Autom Constr. 2018;94:22–38. https://doi.org/10.1016/j.autcon.2018.05.028 .

WCED (World Commission on Environment and Development). Our common future (Oxford paperbacks). Oxford: Oxford University Press; 1987.

Karakhan AM, Gambatese JM. Identification, quantification, and classification of potential safety risk for sustainable construction in the United States. J Constr Eng Manag. 2017. https://doi.org/10.1061/(asce)co.1943-7862.0001302 .

Perrot A, Rangeard D, Courteille E. 3D printing of earth-based materials: processing aspects. Constr Build Mater. 2018;172:670–6. https://doi.org/10.1016/j.conbuildmat.2018.04.017 .

Zhang Z, Provis J, Reid A, Wang H. Geopolymer foam concrete: an emerging material for sustainable construction. Constr Build Mater. 2014;56:113–27. https://doi.org/10.1016/j.conbuildmat.2014.01.081 .

Xia M, Nematollahi B, Sanjayan J. Printability, accuracy and strength of geopolymer made using powder-based 3D printing for construction applications. Autom Constr. 2019;101:179–89. https://doi.org/10.1016/j.autcon.2019.01.013 .

OECD. Material resources, productivity and the environment. OECD green growth studies. Paris: OECD Publishing; 2015. https://doi.org/10.1787/9789264190504-en .

Zou P, Zhang G. Comparative study on the perception of construction safety risks in China and Australia. J Constr Eng Manag. 2009;135(7):620–7. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000019 .

Whirlwind Team. Impacts of 3D printing on the construction industry. https://www.whirlwindsteel.com/blog/impacts-of-3d-printing-on-the-construction-industry . Accessed 15 Dec 2019.

Costanzi C, Ahmed Z, Schipper H, Bos F, Knaack U, Wolfs R. 3D printing concrete on temporary surfaces: the design and fabrication of a concrete shell structure. Autom Constr. 2018;94:395–404. https://doi.org/10.1016/j.autcon.2018.06.013 .

Perkins I, Skitmore M. Three-dimensional printing in the construction industry: a review. Int J Constr Manag. 2015;15(1):1–9. https://doi.org/10.1080/15623599.2015.1012136 .

Panda B, Tay Y, Paul S, Tan M. Current challenges and future potential of 3D concrete printing. Mater Sci Eng Technol. 2018;49(5):666–73. https://doi.org/10.1002/mawe.201700279 .

Paul S, Tay Y, Panda B, Tan M. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch Civ Mech Eng. 2018;18(1):311–9. https://doi.org/10.1016/j.acme.2017.02.008 .

Bridges SM, Keiser K, Sissom N, Graves SJ. Cyber security for additive manufacturing. In: Proceedings of the 10th annual cyber and information security research conference article no. 14, New York, 2015. New York: ACM International Conference Proceedings Series; 2015. https://doi.org/10.1145/2746266.2746280 .

Berman B. 3D printing: the new industrial revolution. IEEE Eng Manag Rev. 2013. https://doi.org/10.1109/emr.2013.6693869 .

Shakor P, Nejadi S, Paul G. A study into the effect of different nozzles shapes and fibre-reinforcement in 3D printed mortar. Materials. 2019;12:1708. https://doi.org/10.3390/ma12101708 .

Kreiger MA, MacAllister BA, Wilhoit JM, Case MP. The current state of 3D printing for use in construction. In: Proceedings of the 2015 conference on autonomous and robotic construction of infrastructure, Ames, Iowa; 2015. pp. 149–158.

Hwang B, Shan M, Supa’at N. Green commercial building projects in Singapore: critical risk factors and mitigation measures. Sustain Cities Soc. 2017;30(7):237–47. https://doi.org/10.1016/j.scs.2017.01.020 .

El-Sayegh S, Manjikian S, Ibrahim A, Abouelyousr A, Jabbour R. Risk identification and assessment in sustainable construction projects in the UAE. Int J Constr Manag. 2018. https://doi.org/10.1080/15623599.2018.1536963 .

Robinson P. Project learning with 3D printing: 3D materials and construction possibilities. New York: Cavendish Square Publishing; 2018. https://ebookcentral.proquest.com/lib/aus-ebooks/reader.action?docID=5404812 . Accessed 7 Apr 2019. ISBN 9781502631473.

Zayed T, Amer M, Pan J. Assessing risk and uncertainty inherent in Chinese highway projects using AHP. Int J Project Manag. 2008;26(4):408–19. https://doi.org/10.1016/j.ijproman.2007.05.012 .

Al-Hajj A, Hamani K. Material waste in the UAE construction industry: main causes and minimization practices. Archit Eng Des Manag. 2011;7(4):221–35. https://doi.org/10.1080/17452007.2011.594576 .

Popov G, Lyon BK, Hollcroft B. Risk assessment: a practical guide to assessing operational risks. 2016. https://ebookcentral.proquest.com . Accessed 15 Dec 2019. ISBN-13: 978-1628251845.

Mathews K. Avoid common robotics hazards by following these 6 rules. 2019. Blog.robotiq.com. https://blog.robotiq.com/avoid-these-common-robotics-hazards-by-following-these-6-rules . Accessed 2 Feb 2019.

Chinniah Y. Robot safety: overview of risk assessment and reduction. Adv Robot Autom. 2016. https://doi.org/10.4172/2168-9695.1000139 .

Li R. An economic analysis on automated construction safety: internet of things, artificial intelligence and 3D printing. Singapore: Springer; 2017. https://doi.org/10.1007/978-981-10-5771-7 .

Salet T, Ahmed Z, Bos F, Laagland H. Design of a 3D printed concrete bridge by testing. Virtual Phys Prototyp. 2018;13(3):222–36. https://doi.org/10.1080/17452759.2018.1476064 .

Kartam N, Kartam S. Risk and its management in the Kuwaiti construction industry: a contractors’ perspective. Int J Project Manag. 2001;19(6):325–35. https://doi.org/10.1016/S0263-7863(00)00014-4 .

Tang W, Qiang M, Duffield C. Risk management in the Chinese construction industry. J Constr Eng Manag. 2007;133(12):944–56. https://doi.org/10.1061/(ASCE)0733-9364(2007)133:12(944) .

Chapman R. The controlling influences on effective risk identification and assessment for construction design management. Int J Project Manag. 2001;19(3):147–60. https://doi.org/10.1016/S0263-7863(99)00070-8 .

Wang S, Dulaimi M, Aguria M. Risk management framework for construction projects in developing countries. Constr Manag Econ. 2004;22(3):237–52. https://doi.org/10.1080/0144619032000124689 .

Travelers.com. 2019. https://www.travelers.com/iw-documents/business-insurance/tech-3D-whitepaper-BTCWH.0003D.pdf . Accessed 2 Feb 2019.

Sköld G, Vidarsson H. Analyzing the potentials of 3D-printing in the construction industry. A thesis in supply chain management (master’s thesis). Chalmers University of Technology, Gothenburg, Sweden, 2015.

Bak D. Rapid prototyping or rapid production? 3D printing processes move industry towards the latter. Assem Autom. 2003;23(4):340–5. https://doi.org/10.1108/01445150310501190 .

Zeltmann S, Gupta N, Tsoutsos N, Maniatakos M, Rajendran J, Karri R. Manufacturing and security challenges in 3D printing. JOM. 2016;68(7):1872–81. https://doi.org/10.1007/s11837-016-1937-7 .

Panda B, Paul SC, Tan MJ. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater Lett. 2017;209:146–9. https://doi.org/10.1016/j.matlet.2017.07.123 .

Workplace health and safety Queensland. Guide to machinery and equipment safety. 2015. https://www.worksafe.qld.gov.au/__data/assets/pdf_file/0010/82783/guidetomachinery-equipmentsafety.pdf . Accessed 15 Dec 2019.

Sweis G, Sweis R, Abuhammad A, Shboul A. Delays in construction projects: the case of Jordan. Int J Project Manag. 2008;26(6):665–74. https://doi.org/10.1016/j.ijproman.2007.09.009 .

Ling F, Hoi L. Risks faced by Singapore firms when undertaking construction projects in India. Int J Project Manag. 2006;24(3):261–70. https://doi.org/10.1016/j.ijproman.2005.11.003 .

Zou P, Zhang G, Wang J. Understanding the key risks in construction projects in China. Int J Project Manag. 2007;25(6):601–14. https://doi.org/10.1016/j.ijproman.2007.03.001 .

El-Sayegh S, Mansour M. Risk assessment and allocation in highway construction projects in the UAE. J Manag Eng. 2015. https://doi.org/10.1061/(asce)me.1943-5479.0000365 .

Faridi A, El-Sayegh S. Significant factors causing delay in the UAE construction industry. Constr Manag Econ. 2006;24(11):1167–76. https://doi.org/10.1080/01446190600827033 .

Ghosh S, Jintanapakanont J. Identifying and assessing the critical risk factors in an underground rail project in Thailand: a factor analysis approach. Int J Project Manag. 2004;22(8):633–43. https://doi.org/10.1016/j.ijproman.2004.05.004 .

Doloi H, Sawhney A, Iyer K, Rentala S. Analysing factors affecting delays in Indian construction projects. Int J Project Manag. 2012;30(4):479–89. https://doi.org/10.1016/j.ijproman.2011.10.004 .

Al-Saleh Y, Taleb H. The integration of sustainability within value management practices: a study of experienced value managers in the GCC countries. Project Manag J. 2010;41(2):50–9. https://doi.org/10.1002/pmj.20147 .

Fang D, Li M, Fong PS, Shen L. Risks in Chinese construction market—contractors’ perspective. J Constr Eng Manag. 2004;130(6):853–61. https://doi.org/10.1061/(ASCE)0733-9364(2004)130:6(853) .

Zhi H. Risk management for overseas construction projects. Int J Project Manag. 1995;13(4):231–7. https://doi.org/10.1016/0263-7863(95)00015-I .

Download references

This work was supported in part by funding from the American University of Sharjah (Grant No. EFRG18-SCR-CEN-42).

Author information

Authors and affiliations.

Department of Civil Engineering, American University of Sharjah, Sharjah, UAE

S. El-Sayegh & S. Manjikian

Department of Mechanical Engineering, American University of Sharjah, Sharjah, UAE

L. Romdhane

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to S. El-Sayegh .

Additional information

Publisher’s note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Reprints and permissions

About this article

El-Sayegh, S., Romdhane, L. & Manjikian, S. A critical review of 3D printing in construction: benefits, challenges, and risks. Archiv.Civ.Mech.Eng 20 , 34 (2020). https://doi.org/10.1007/s43452-020-00038-w

Download citation

Received : 22 February 2020

Accepted : 03 March 2020

Published : 10 March 2020

DOI : https://doi.org/10.1007/s43452-020-00038-w

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- 3D printing in construction

- Smart construction

- Risk management

- Find a journal

- Publish with us

- Track your research

University of California Thesis: Reviewing 3D Printing in Construction, Including Mars

Share this Article

Andrew Truong recently presented a thesis, ‘ State-of-the-Art Review on 3D Printing Technology Applications in Construction ,’ to the University of California , Irvine. Reviewing 3D printing in construction, Truong tackles a multi-faceted topic regarding materials, technique, and the future of the industry—even going as far as discussing the potential for construction on Mars.

Today industrial users may be experimenting with new modes of production , different composites , or working on a larger scale with concrete, but while so many benefits are available, challenges still remain too. This leaves researchers a lot of room for discussion and experimentation, and especially as new projects with different requirements arise.

Truong takes his readers on a short foray through the history and emergence of 3D printing in the mainstream, noting especially its impacts on applications within medicine, the emergence of RepRap Open Source and Makerbot , and the growing popularity of FDM 3D printing overall. With the opportunity for making big headlines, numerous companies have built homes, touting record speed, and huge potential for economic residences in the future.

The first version of RepRap design (Mendel) [Source: https://reprap.org/wiki/Build_A_RepRap]

“In the construction industry, 3D printing is used to manufacture structures with nearly zero waste, minimum costs, and faster building time. Within days, depending on the complexity and size of building, a new structure can be built that can be customized for each building iteration,” explains Truong. “Houses built using 3D printing technology can be achieved by a variety of ways and each method of construction has its advantage and disadvantages.”

3D concrete printer in operation. No-slump concrete leaves the nozzle as a relatively stiff continuous filament. [23]

3DCP facility at the TU Eindhoven, with some examples of printed objects [23]

“The high resolution of the printing makes it able to print thin layers that are refined to have a finish exterior on the print. This nozzle houses the extrusion screw auger motor that pumps out the concrete before it is place on the 3D print,” states Truong. “The printer then moves in the direction and orientation of the printer to accurately 3D print the object. Therefore, the extrusion system has two motors. One motor is used to dispense the concrete out of the nozzle. The other motor is used to orient the nozzle in the correct direction. The shape of this nozzle creates a fine layer instead of a glob bead. The fine layer creates way for the 3D printer to have fine resolution prints in the same way a thermoplastic 3D printer works with a different print material and nozzle extruder.”

Printer head and nozzle. [23]

- Thermoplastics

- Photopolymers

The use of formworks in construction can lead to longer time in production, more waste of materials, and greater expense; with more streamlined techniques avoiding the need for frameworks, industrial users experience more latitude in design and actual ‘building.’ In constructing homes, no formworks are required.

“Doors and windows are built by placing a beam across the overhead gap while 3D printing or modular piece by piece construction is used,” said Truong. “After the house walls are 3D printed, the roof is then built to complete the structure. Mechanical, electrical, and plumbing can then be surface mounted to the structure. The exterior design of the house can be a layering pattern due to 3D printing or finish grout can be applied to create a smooth surface indistinguishable from traditional concrete building methods.”

Equipment can be and is routinely modified by engineers developing projects for different applications.

CyBe® Robotic Arm [38]

Apis Cor Crane Printer. [40]

WASP 3D Printed Geo House [41]

“Since Mars is covered with a regolith that can be used for in-situ construction, building on Mars is also economically feasible. 3D printing is an emerging field in construction that builds concrete formwork layer by layer without the use of molds nor forms. The feedstock used in 3D printing concrete requires a mix design that uses fine particles, because the feedstock must have a viscosity and workability that is able to flow through an extrusion and dynamic pump system,” states Truong. “The concrete mix will be 3D printable based on buildable layers, flowability through the system, and low gravitational out gassing [55]. The material properties of the mix design should also be structural enough to be used as radiation shielding and resilient to brittle cracking which induces a loss of cabin pressure in order be used in the Martian environment.”

The author goes into numerous designs created for Mars habitat challenges, yielding extremely interesting results.

Team AI. SpaceFactory of New York is the second-place winner in NASA’s 3D-Printed Habitat Challenge, Phase 3: Level 1 competition. [49]

Team Kahn-Yates from Jackson, Mississippi, won third place in Phase 3: Level 1 of NASA’s 3D-Printed Habitat Challenge. The team virtually designed a Mars habitat specifically suited to withstand dust storms and harsh climates on the red planet. [50]

“Research and development into the range of applications of 3D printing in construction is the beginning of a new building industry standard. The development of multistory construction will further increase market viability. While automated reinforcement, mechanical, electrical, and plumbing will increase construction speed and architectural design. The development of 3D printing thermoplastics with timber composites will make 3D printed houses competitive with suburban houses because homeowners will be able to hang picture frames and cabinets without anchoring into concrete,” concluded the author. “Prices for timber 3D printing filament is like 3D printing thermoplastics, because of the lack of an industrialized method of manufacturing the timber filament. Since the filaments are 77 made of sawdust, the filament should be able to be manufactured at a lower price. Several develops in the 3D printing construction industry will lead to the ubiquity of 3D printing construction and infrastructural changes in construction will provide an efficient method of building.”

What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com .

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

- Enter your email address *

- Name This field is for validation purposes and should be left unchanged.

Recent News

AM Data Slice: 3D Printing Materials to Reach $3.9B in 2024

3D Printing Unpeeled: Biofuel Waste to Filament & Sustainable Photopolymers

3D Printed Art

3D Printed Food

3D Printed Guns

You May Also Like

Nsf awards kentucky $1m for advanced manufacturing.

The National Science Foundation has awarded a $1 million grant to the University of Louisville for the Advancing Manufacturing and Building Construction Technologies (NSF AMT) project. This initiative is part...

3D Printing News Briefs, May 11, 2024: 3D Printed Stent, Tower, Sculptures, & More

We’re starting off with medical research in today’s 3D Printing News Briefs, as researchers in Korea used CT images and 3D printing to fabricate an educational simulator for a mastoidectomy....

3D Printing Unpeeled: Wind Turbines, Probiotics and Lenses

TPI Composites, ORNL and Ingersoll Rand are working to make wind turbine tooling segments that can be 18.3 meters long. These elements also include resistive wires that help keep the...

Tethon 3D Releases Cost-effective Bioprinter

Tethon 3D, known for its ceramic-loaded DLP materials, custom resins, and DLP 3D printers, has recently released a bioprinter. Vat polymerization printers like DLP systems have been widely used by...

Print Services

Upload your 3D Models and get them printed quickly and efficiently.

- 3DPrinting Business Directory

Site Sponsor

Additive Manufacturing Strategies

Networking & Intelligence Summit, February 4-6, 2025

3D Printing jobs around the world.

- I would like to also register for free and access proprietary industry data from SmarTech and 3DPrint.com

3D Printing Guides

- Desktop 3D Printer Buyer’s Guide

- 3D Scanner Buyer's Guide

- Metal 3D Printer Guide

- Industrial Polymer 3D Printer Guide

- The 3D Systems Zone

- The HP Zone

- Desktop Metal Zone

- Bioprinting Zone

- The Space Zone

- 3D Printing Stocks Zone

Register to view and download proprietary industry data from AM Research and 3DPrint.com Questions? Contact [email protected]

Already have an account?

- First name *

- Last name *

- Password * Enter Password Confirm Password

- I agree to receive the 3DPrint.com Daily newsletter and promotional email correspondence.

- Comments This field is for validation purposes and should be left unchanged.

The Emergence of 3D Printing

Add to collection, downloadable content.

- March 20, 2019

- Affiliation: College of Arts and Sciences, Department of Public Policy

- The purpose of this dissertation is to investigate 3D printing that is expected to provide a foundation for long-term and sustainable economic growth from a policy perspective. This dissertation first explores how 3D printing transforms traditional manufacturing and how it influences regional economies. It then provides a novel approach for how 3D printing invention is identified according to patent data created between 1985 and 2013 filed in the United States Patent and Trademark Office (USPTO). From the unique dataset, this dissertation offers ample empirical evidence on the geographic diffusion of 3D printing, the key locations of inventive activity in 3D printing, the major groups of developing 3D printing, and user firms and their industrial sectors. Using the dataset, this dissertation empirically demonstrates how 3D printing diffuses across the 366 United States (U.S.) metropolitan statistical areas (MSAs) and how MSAs construct a competitive advantage for 3D printing of user firms. The results from two models show the role of industrial structure in the diffusion of 3D printing and the role of universities, individual inventors, and 3D printer manufacturers in establishing a competitive advantage for 3D printing. Overall, this dissertation contributes to the theoretical and empirical understanding of the process by which a region is successful in developing emerging technology by highlighting regional conditions and capability for the successful introduction of emerging technology and the importance of multiple actors for the construction of a competitive advantage.

- 3D Printing

- Technology Diffusion

- Additive Manufacturing

- Public policy

- Regional Competitive Advantage

- Economic Geography

- General Purpose Technology

- https://doi.org/10.17615/sd48-rj68

- Dissertation

- In Copyright

- Gitterman, Daniel

- Lester, T. William

- Lowe, Nichola

- Feldman, Maryann

- Moulton, Jeremy

- Doctor of Philosophy

- University of North Carolina at Chapel Hill Graduate School

This work has no parents.

Select type of work

Master's papers.

Deposit your masters paper, project or other capstone work. Theses will be sent to the CDR automatically via ProQuest and do not need to be deposited.

Scholarly Articles and Book Chapters

Deposit a peer-reviewed article or book chapter. If you would like to deposit a poster, presentation, conference paper or white paper, use the “Scholarly Works” deposit form.

Undergraduate Honors Theses

Deposit your senior honors thesis.

Scholarly Journal, Newsletter or Book

Deposit a complete issue of a scholarly journal, newsletter or book. If you would like to deposit an article or book chapter, use the “Scholarly Articles and Book Chapters” deposit option.

Deposit your dataset. Datasets may be associated with an article or deposited separately.

Deposit your 3D objects, audio, images or video.

Poster, Presentation, Protocol or Paper

Deposit scholarly works such as posters, presentations, research protocols, conference papers or white papers. If you would like to deposit a peer-reviewed article or book chapter, use the “Scholarly Articles and Book Chapters” deposit option.

- < Previous

UKnowledge > College of Engineering > Mechanical Engineering > Theses & Dissertations > 144

Theses and Dissertations--Mechanical Engineering

Design and process of 3d-printed parts using composite theory.

Jordan Garcia , University of Kentucky Follow

Author ORCID Identifier

https://orcid.org/0000-0002-5328-4882

Date Available

Year of publication, degree name.

Master of Science in Mechanical Engineering (MSME)

Document Type

Master's Thesis

Engineering

Department/School/Program

Mechanical Engineering

First Advisor

Dr. Y. Charles Lu

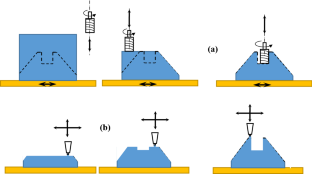

3D printing is a revolutionary manufacturing method that allows the productions of engineering parts almost directly from modeling software on a computer. With 3D printing technology, future manufacturing could become vastly efficient. However, it is observed that the procedures used in 3D printing differ substantially among the printers and from those used in conventional manufacturing. In this thesis, the mechanical properties of engineering products fabricated by 3D printing were comprehensively evaluated and then compared with those made by conventional manufacturing. Three open-source 3D printers, i.e., the Flash Forge Dreamer, the Tevo Tornado, and the Prusa, were used to fabricate the identical parts out of the same material (acrylonitrile butadiene styrene). The parts were printed at various positions on the printer platforms and then tested in bending. Results indicate that there exist substantial differences in mechanical responses among the parts by different 3D printers. Specimens from the Prusa printer exhibit the best elastic properties while specimens from the Flash Forge printer exhibit the greatest post-yield responses. There further exist noticeable variations in mechanical properties among the parts that were fabricated by the same printer. Depending on the positions that the parts were placed on a printer platform, the properties of resultant parts can vary greatly. For comparison, identical parts were fabricated using a conventional manufacturing method, i.e., compression molding. Results show that compression molded parts exhibit more robust and more homogeneous properties than those from 3D printing. During 3D printing, the machine code (e.g., the Gcode) would provide the processing instructions (the x, y, and z coordinates and the linear movements) to the printer head to construct the physical parts. Often times the default processing instructions used by commercial 3D printers may not yield the optimal mechanical properties of the parts. In the second part of this thesis, the orientation-dependent properties of 3D printed parts were examined. The multi-layered composite theory was used to design the directions of printing so that the properties of 3D printed objects can be optimized. Such method can potentially be used to design and optimize the 3D printing of complex engineering products. In the last part of this thesis, the printing process of an actual automobile A-pillar structure was designed and optimized. The finite element software (ANSYS) was used to design and optimize the filament orientations of the A-pillar. Actual parts from the proposed designs were fabricated using 3D printer and then tested. Consistent results have been observed between computational designs and experimental testing. It is recommended that the filament orientations in 3D-printing be “designed” or “tailored” by using laminate composite theory. The method would allow 3D printers to produce parts with optimal microstructure and mechanical properties to better satisfy the specific needs.

Digital Object Identifier (DOI)

https://doi.org/10.13023/etd.2019.418

Recommended Citation

Garcia, Jordan, "DESIGN AND PROCESS OF 3D-PRINTED PARTS USING COMPOSITE THEORY" (2019). Theses and Dissertations--Mechanical Engineering . 144. https://uknowledge.uky.edu/me_etds/144

Since November 05, 2019

Included in

Computer-Aided Engineering and Design Commons , Manufacturing Commons , Polymer and Organic Materials Commons

Advanced Search

- Notify me via email or RSS

Browse by Author

- Collections

- Disciplines

Author Corner

- Submit Research

New Title Here

Below. --> connect.

- Law Library

- Special Collections

- Copyright Resource Center

- Graduate School

- Scholars@UK

- We’d like your feedback

Home | About | FAQ | My Account | Accessibility Statement

Privacy Copyright

University of Kentucky ®

An Equal Opportunity University Accreditation Directory Email Privacy Policy Accessibility Disclosures

85 3D Printing Essay Topic Ideas & Examples

🏆 best 3d printing topic ideas & essay examples, ⭐ most interesting 3d printing topics to write about.

- 💡 Good Essay Topics on 3D Printings

❓3D Printing Research Questions

- 3D Printing Industry and Market One can understand the industry of 3D technologies in terms of the software technology, the hardware and the nature of the products.

- 3D Printing in the Medical Field The key issue in the field of bioprinting remains the areas of application in medicine and the establishment of certain boundaries for this technology.

- 3D Printing Development for Fashion Industry The fashion industry was not moved or altered by 3D printing during the earlier days because most of the inventions covered the need to modify and improve the printing capability.

- UAE Government Foresight and Scenarios Program: The 3D Concrete Printing The 3D concrete printing initiative is the future of modernised, affordable, durable, and efficient means of construction for government projects across the UAE.

- 3D Printed Food and Utensils Safety The former is typically implemented in the production of simple foods and components, whereas the latter is used in combined culinary, with the implementation of both natural and printed ingredients.

- 3D Printing Technology in Medicine Notably, doctors need to learn how to use the printer in developing organs for patients in need of them. Employees need to be trained on how to use it at the workplace.

- 3D Heart Printing and Its Future Lee and Dai attributed the probability of the success of 3D technology to the materials used since they support the cellular components during and after bioprinting procedures.

- 3D Printing: Pros and Cons The authors compare the quick advancement and loss in the price of 3D printers with the rise of the personal computers.

- 3D Printer Elements and Features The objects that can be created with this printer should be at least 5x5x5 inches. These are some of the details that should be considered by the seller.

- Technology and Business: 3D Printer Impact This paper outlines the technology used for a Form 1 3D printer, as well as the impact this technology has had on business over the past ten years, the future of technology and business, the […]

- 3D Bioprinting of Physical Organs This sort of technology can be compared to the current prostatic usage and it has proven to be extremely beneficial for people.

- 3D Printing as Third Industrial Revolution Another significant advantage of 3D printing is that it leads to increased efficiency as nearly all raw material can be utilized in the manufacturing process.

- 3D Printing Industry in the UK Moreover, this research related the background of Makism 3D Corporation and the future of the 3D industry in the United Kingdom.

- Process Description: 3D Printing The material is the string-like strand of plastic coiled in the back of the printer. In turn, the movement of the print head is directed by the 3D file sent to the printer.

- 3D Bioprinting of Brown Adipose Tissue

- Additive Manufacturing: 3D Printing and the Future of Organizational Design

- Charting the Environmental Dimensions of Additive Manufacturing and 3D Printing

- 3D Printing and the Future of Nursing Education

- Current Applications and Future Perspectives of the Use of 3D Printing

- Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing

- 3D Printing and Its Effects on the World of Manufacturing

- Innovation Ecosystems Across Science, Technology, and Business: 3D Printing in China

- Financial and Funding Plan for a Biotech 3D Printing Company

- 3D Printing Food: Fiction or Reality?

- History, Future, and Applications of 3D Printing

- Limitations and Common Issues With 3D Printing

- Making Rare Materials Hands-On: 3D Printing a Possibility for Rare Materials

- Moral and Ethical Implications of 3D Printing Technology

- Nanoparticle Exposure During Processes Related to a Metal Object 3D Printing

- New Industrial Platforms and Radical Technology Foresight: 3D Printing in Europe

- 3D Printing Materials: Status, Opportunities, Market Forecasts

- Professional Skills for Information Technology for 3D Printing

- Reviewing Gun Control and 3D Printing in America

- Strategic Marketing Recommendation for the Launch of a 3D Printing Machine

💡 Good Essay Topics on 3D Printing

- Successful Business Models for 3D Printing Companies

- The Challenges and Boundaries of 3D Printing

- Overview of the Current Medical Uses of 3D Printing

- The Development and Challenge of 3D Printing

- The Different Areas and Applications of 3D Printing

- The Relationship Between Medical and Dental Industry and 3D Printing

- Biomimetic Scaffolds for Tissue Engineering: 3D Printing Techniques in Regenerative Medicine

- Tripolyphosphate-Crosslinked Chitosan & Gelatin Biocomposite Ink for 3D Printing of Uniaxial Scaffolds

- Understanding the Main Uses of 3D Printing

- The Potential Uses of 3D Printing Technology in the Modern World

- The Positive Impact of 3D Printing on Our Health and the Environment

- Why 3D Printing Service Bureaus Need to Be Automated

- The Effect of Three-Dimensional Printing on Prosthetic Limbs

- 3D Printing: Yesterday, Today, and Tomorrow

- The Link Between 3D Printing and Bioprinting Revolutionizing Healthcare

- 3D Printing Usage to Boost Competitive Advantage of American Manufacturing

- Technology and Ecology: Inventions With 3D Printer That Will Surprise You

- Development of Direct Metal Laser Sintering Machine

- 3D Printing and Its Effects on the Economy

- Digital Printing and Its Impact on the 3D Printing Future Growth

- What Are the Positive and Negative Impacts of 3D Printing?

- How Does 3D Printing Help Society?

- Can 3D Printing Make Everything?

- What Are the Potential Uses of 3D Printing?

- Is 3D Printing Used in Business Today?

- What Could 3D Printing Be Used for in the Future?

- Does 3D Printing Use Artificial Intelligence?

- How Does 3D Printing Affect the Modern Industry?

- Who Will Benefit the Most From 3D Printing?

- How Is 3D Printing Changing the World?

- Is 3D Printing Technology Improving?

- What Problems Can 3D Printing Solve?

- Is 3D Printing the Future of Sustainable Manufacturing?

- Does 3D Printing Save Energy?

- Will 3D Printing Change the World?

- How Can 3D Printing Help the Environment?

- What Is the Use of 3D Printing in Modern Technology?

- Can 3D Printing Help the Economy?

- How Is 3D Printing Used in Medicine?

- Is 3D Printing the Future of Fashion?

- Where Is 3D Printing Used in Industry?

- How Is 3D Printing Advancing the World We Live In?

- Which Industries Use 3D Printing Most?

- Can 3D Printing Help Developing Countries?

- What Is the Future Growth of 3D Printing?

- Is 3D Printing Good for the Environment?

- What Products Are Made Using 3D Printing?

- Does the Aerospace Industry Use 3D Printing Services?

- Why Is 3D Printing Important for the Future?

- Can 3D Printing Be Used for Architecture?

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2023, September 26). 85 3D Printing Essay Topic Ideas & Examples. https://ivypanda.com/essays/topic/3d-printing-essay-topics/

"85 3D Printing Essay Topic Ideas & Examples." IvyPanda , 26 Sept. 2023, ivypanda.com/essays/topic/3d-printing-essay-topics/.

IvyPanda . (2023) '85 3D Printing Essay Topic Ideas & Examples'. 26 September.

IvyPanda . 2023. "85 3D Printing Essay Topic Ideas & Examples." September 26, 2023. https://ivypanda.com/essays/topic/3d-printing-essay-topics/.

1. IvyPanda . "85 3D Printing Essay Topic Ideas & Examples." September 26, 2023. https://ivypanda.com/essays/topic/3d-printing-essay-topics/.

Bibliography

IvyPanda . "85 3D Printing Essay Topic Ideas & Examples." September 26, 2023. https://ivypanda.com/essays/topic/3d-printing-essay-topics/.

- Digital Transformation Topics

- Contemporary Art Questions

- Robots Questions

- Pop Art Titles

- Tattoo Research Ideas

- Cyberspace Topics

- Data Mining Titles

- Plastic Surgery Essay Titles

3D Printing - List of Free Essay Examples And Topic Ideas

3D Printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. Essays on 3D printing could explore its evolution, various applications across industries like healthcare, automotive, and aerospace, and its potential to revolutionize manufacturing. Discussions could also include the environmental impact and ethical implications of 3D printing. We’ve gathered an extensive assortment of free essay samples on the topic of 3D Printing you can find at Papersowl. You can use our samples for inspiration to write your own essay, research paper, or just to explore a new topic for yourself.

The Importance of 3d Printing these Days

We board a fast world wherever everything is needed quickly then, will be} wherever 3D printing can extremely build a distinction. one amongst the massive benefits of 3D printing is that components and product will be factory-made plenty faster than they'll mistreatment ancient ways. complicated styles will be created as a CAD model then reworked into a reality in precisely some hours. This delivers style ideas during a manner that allows them to be verified quickly and designed during a […]

3D Printing and the Future of Nursing Education

With the progress in technology, the contemporary world has become much more advanced than it was even ten years ago. Thus, the existing technology now serves the population in numerous industries and areas, and its assistance makes the lives of people more convenient and simpler. Moreover, the positive impact of technological progress appears to play a vital role in the life of the entire population, as people have been using various technologies specifically in the field of healthcare for many […]

3d Printed Guns It is Constitutional

Even though this is an incredibly new technology, politicians and even presidents around the globe makers have recognized 3D printed guns and what’s behind it. Regardless of what their actual thoughts are on the topic, the laws that they have tried to put into place that obstructs the progress of the technology has risen the number of questions that deal with it. Questions such as whether or not it is constitutional to make them, distribute them or even use them. […]

We will write an essay sample crafted to your needs.

3D Printing and Bioprinting Revolutionizing Healthcare

3D bioprinting is one of the most anticipating and promising technological advancements of all time. According to the US National Library of Medicine, 3D bioprinting is "a manufacturing method in which objects are made by fusing or depositing materials? such as plastic, metal, ceramics, powders, liquids, or even living cells? in layers to produce a 3D object" (Ventola, 2014, para 2). Is With the capability of using real cells, 3D bioprinting will make it possible to create living tissue. This […]

3D Printing Yesterday Today and Tomorrow

There are a few 3D printing key terms that need to be mentioned prior to going into full detail of the subject. These terms and/or abbreviations may be mentioned throughout this project. (ABS) Acrylonitrile butadiene styrene- ABS is a thermoplastic that is the material that some 3D printers use when modeling 3D printers. On a side note some do not like using it because it gives off a foul odor from the burning of the plastic filament. Filament- Filament is […]

Virtual Reality: Game Transfer Phenomena

Imagine if you were you were floating through space, watching a horror film,s or perhaps playing a video game, and it seemed like you were actually there. With the invention of virtual reality (VR), people are able to explore the illusion of this reality. Virtual reality is computer-generated technology used to create a manufactured environment. There is a range of systems that are used for this purpose such as special headsets and fiber optic gloves. The term virtual reality means […]

Why 3D Printing Service Bureaus Needs to be Automated

According to Research and Markets forecast, 3D printing services market expected to grow to more than $13 billion from 2017 to 2022. With this rapidly increasing and overwhelming demand for 3D printing services holds enormous potential and business opportunities for 3D printing service bureaus. However, as the 3D printing market grows, employees are facing the challenge of scaling their current process, especially when quoting or delivering unmanaged services. To overcome this problem and stay on track with the competitors, many […]

3D Printing in Business

Abstract This paper explores the advantages and disadvantages of 3D printing and future implementation into the realm of business. The future of 3D printing has yet to be known and is being implemented into markets all over the world. I feel that the business industry can capitalize upon this advancement in technology and use it to its full ability. This paper will go into detail on how it's being implemented into other industries and how it will be vital to […]

The Effect of Three Dimensional Printing on Prosthetic Limbs

Most of the population takes having working limbs for granted. Around 2 million people need prosthetic limbs to function in their daily life. Patients with prosthetic limbs sometimes have problems with the prosthetic piece either not fitting them or being uncomfortable. The small steps in the prosthetic industry have made some problems go away; three-dimensional printing is a big leap in personalized prosthetics. Three-dimensional printing, a more personal and efficient way to make prosthetic limbs compared to traditional methods, is […]

3d Printing Dilenma

The case study discusses the moral issues raised about 3D printing of human organs. According to the case study, one of the moral dilemmas is the social implications of 3D printing versus its importance in improving the quality of life of human beings. The second dilemma concerns the ethics of prolonging life beyond the current life expectancy considering issues such as overpopulation that threaten the world. In the following paper, the moral dilemmas will be discussed, and solutions identified that […]

The Execution of 3-D Printing

Environmental Factors. The execution of 3-D printing in the manufacturing process could prevent some types of harmful environmental issues since its production produces nearly zero waste. Also, the capability of 3-D printing in manufacturing will decrease the harmful environmental effects which come from the transportation of goods around the world. Bringing 3-D printing into manufacturing would significantly reduce environmental damage during the shipment of goods. (Reichardt, 2014) The environment stands to gain much from the emerging technology of 3-D printing. […]

The Viability of 3D Printers as a Consumer Shopping Solution

As technology advances around the world, there has become a need for instinct gratification. The easy availability of materials has allowed society to have everything people ever desire at the tips of their fingers. Every year, more proposals for updates on technology are invented in hopes to expand the industrial science world. In today's world, there is a huge discussion over the topic of 3D printing becoming a regular program for shopping and consumer goods from the convenience of homes. […]

3D Bioprinting of Brown Adipose Tissue

The vascularized tissue that I would like to 3D bioprint is brown adipose tissue. Brown adipose tissue is a fatty tissue that is used in the body to generate heat from energy stored in the form of lipids (5). Brown adipose tissue is primarily found in human babies, hibernating animals, and human adults that are in need of an extra source of heat. In most adults however, a majority of the brown adipose tissue that was prevalent as a child […]

How See Now, Buy Now Enabled by Artificial Intelligence

Walter Mischel, a psychologist famed for the 1960's Marshmallow Test, which he elucidated the virtue of delayed gratification for youngsters. Today, the data economy promotes the dichotomy of an on-demand culture. Enabled by AI on divinatory consumer demand and predictive supply chain, front-line companies are charged up to provide a See-Now-Buy-Now (SNBN) experience to the consumers. Amongst the US retail categories, grocery ranks first with $770 billion (30% of dollar share), while apparel second at $310 billion. After the acquisition […]

Additional Example Essays

- Robots Taking Over Jobs

- Benefits Of Artificial Intelligence

- Leadership and the Army Profession

- Why Abortion Should be Illegal

- Death Penalty Should be Abolished

- Positive Effects of Social Media

- Dogs Are Better Than Cats Essay

- Personal Philosophy of Leadership

- Professions for Women by Virginia Woolf

- Homeless Veterans

- Does Arrest Reduce Domestic Violence

- The Effects of Illegal Immigration

1. Tell Us Your Requirements

2. Pick your perfect writer

3. Get Your Paper and Pay

Hi! I'm Amy, your personal assistant!

Don't know where to start? Give me your paper requirements and I connect you to an academic expert.

short deadlines

100% Plagiarism-Free

Certified writers

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- J Healthc Eng

- v.2019; 2019

The Role of 3D Printing in Medical Applications: A State of the Art

1 Aid4Med S.r.l., Udine 33100, Italy

Augusto Palermo

2 Head 3 Orthopaedic Department, Istituto Auxologico Italiano IRCCS Capitanio Hospital, Milan 20122, Italy

Bernardo Innocenti

3 BEAMS Department, Université Libre de Bruxelles, Bruxelles 1050, Belgium

Three-dimensional (3D) printing refers to a number of manufacturing technologies that generate a physical model from digital information. Medical 3D printing was once an ambitious pipe dream. However, time and investment made it real. Nowadays, the 3D printing technology represents a big opportunity to help pharmaceutical and medical companies to create more specific drugs, enabling a rapid production of medical implants, and changing the way that doctors and surgeons plan procedures. Patient-specific 3D-printed anatomical models are becoming increasingly useful tools in today's practice of precision medicine and for personalized treatments. In the future, 3D-printed implantable organs will probably be available, reducing the waiting lists and increasing the number of lives saved. Additive manufacturing for healthcare is still very much a work in progress, but it is already applied in many different ways in medical field that, already reeling under immense pressure with regards to optimal performance and reduced costs, will stand to gain unprecedented benefits from this good-as-gold technology. The goal of this analysis is to demonstrate by a deep research of the 3D-printing applications in medical field the usefulness and drawbacks and how powerful technology it is.

1. Introduction

Among the different manufacturing processes that are currently adopted by the industry, the 3D printing is an additive technique. It is a process through which a three-dimensional solid object, virtually of any shape, is generated starting from a digital model. Medical 3D printing was once an ambitious pipe dream. However, time and investment made it real. Nowadays, the 3D printing technology represents a big opportunity to help pharmaceutical and medical companies to create more specific drugs, enabling a rapid production of medical implants and changing the way that doctors and surgeons plan procedures [ 1 ]. This technology has multiple applications, and the fastest growing innovation in the medical field has been represented by the advent of the 3D printing itself [ 2 ]. Five technical steps are required to finalize a printed model. They include selecting the anatomical target area, the development of the 3D geometry through the processing of the medical images coming from a CT/MRI scan, the optimization of the file for the physical printing, and the appropriate selection of the 3D printer and materials ( Figure 1 ). This file represents the guidance for the subsequent printing, “slicing” that digital design model into cross sections. That “sliced” design is then sent to a 3D printer, which manufactures the object by starting at the base layer and building a series of layers on top until the object is built using the raw materials that are needed for its composition. A patient-specific model with anatomical fidelity created from imaging dataset is finally obtained.

3D-printing workflow.

In this way, the 3D printing has the potential to significantly improve the research knowledge and the skills of the new generation of surgeons, the relationship between patient and surgeon [ 3 ], increasing the level of understanding of the disease involved, and the patient-specific design of implantable devices and surgical tools [ 4 – 6 ] and optimize the surgical process and cost [ 7 ]. Nowadays, different printing techniques and material are available in order to better reproduce the patient anatomy. Most of the available printing materials are rigid and therefore not optimum for flexibility and elasticity, unlike biological tissue [ 8 ]. Therefore, there are nowadays materials able to close the gap between the real anatomy and the reproduced one, especially considering the soft tissue [ 9 , 10 ]. In this analysis, an overview of the 3D printing application in medical field is presented, highlighting the usefulness and limitations and how it could be useful for surgeons.

2. Additive Manufacturing Technologies

The 3D-printing techniques have grown in the last decades starting from 1986 when the first stereolithographic (SLA) systems were introduced in practice. Seven are the technical processes related to the 3D printing, each of which is represented by one or more commercial technologies, as shown by the ASTM International [ 11 ]. All the processes are listed in Table 1 that reported information about the technologies involved, the materials used, and the medical applications related to each process [ 12 ]. A comparison among all the seven techniques is proposed in the same table showing the advantages and disadvantages related to all the processes. Each process uses specific materials with specific properties that relate to medical applications, which are also summarized in Table 1 . This general information helps the users to better choose the right technology depending on the application needed.

Summary of the 3D-printing process and technologies, focus on materials needed and medical applications, and comparison among the 3D-printing technologies.

These technologies and the related advantages enable the researchers to improve existing medical applications that use 3D-printing technology and to explore new ones. The medical goal that has been already reached is significant and exciting, but some of the more revolutionary applications, such as bio/organ printing, require more time to evolve [ 2 ].

3. Transformation Process and Materials Used

Materials used in 3D printing are transformed during the production of the specific model by changing their consistency. This process is named cure and can be done in different ways: a melting of a hard filament in order to give the desired form to the model by the material distortion, liquid solidification for the construction of the structure and powder solidification. All these processes require filler or support material in lattice forms avoiding distortion of the model while the material is being cured. The support material can be easily removed by hand with a cutting tool; however, there is the risk to leave impression on the surface requiring an additional polishing in order to obtain a good-quality printing. The risk of damaging the model, losing details, or break the geometry is really high [ 23 ].

The correct selection of the material is directly linked to the selection of the 3D-printing process and printer, as well as the requirements of the model. Related to medical application, similarly to other applications, different anatomical structures need different mechanical properties of the materials to fulfill the required performance of the printed object [ 8 ]. The main distinction among the different materials that characterize the human body is between rigid and soft materials. Human bones are an example of rigid tissue and ligaments or articular cartilage are examples of soft materials. Bones are the simplest and easiest biological tissue to be produced by 3D printing as the majority of the materials are rigid. The materials used in 3D printing to model the bone structure are for example acrylonitrile butadiene styrene (ABS) [ 23 ], powder of plasters [ 24 ], and hydroquinone [ 8 ].

Relating to soft tissues, deeper research is still needed in order to decrease the gap between a 3D-printed anatomical model and the human structure. Most of the 3D-printing materials present a lack of realism to mimic adequately a soft human biological tissue. Thus, postprocessing may be necessary in order to soften the printed structures. Some examples are given in the reproduction of cartilaginous tissues [ 25 ], arteries for practicing valve replacement [ 26 ], hepatic segment [ 27 ], and hearts [ 28 ]. An interesting example is the development of a 3D-printed brain aneurysm using the flexible TangoPlus™ photopolymer [ 29 ] that represented a useful tool to plan the operative strategy in order to treat congenital heart disease. Furthermore, some of the materials used are urethane and rubber-like material, mixed with a rigid photopolymer, to reasonably mimic the artery structure due to their Shore value and elastic properties similar to the physiological one [ 30 , 31 ].

For a promising future, the multimaterial composites seem to represent a good chance for the 3D printing of human tissues since none of the current available material is able to fully mimic elastic and biological tissues. Multimaterial composites may be designed based on the capacity of the selected biological material to replicate the mechanical properties of human tissue [ 32 ]. Mechanical testing may represent a necessary tool to analyze the biomechanical response and validate the artificial material.

Moreover, it is also important to mention that 3D printing allows the reproduction of implantable custom device, but still deeper research needs to be done in order to examine the differences between the traditional and additive manufacturing in terms of mechanical and structural properties, especially fatigue limit needs to be examined further [ 33 ].

4. Role of 3D Printing in Medical Field

Every year, 3D printing offers more and more applications in the healthcare field helping to save and improve lives in ways never imagined up to now. In fact, the 3D printing has been used in a wide range of healthcare settings including, but not limited to cardiothoracic surgery [ 34 ], cardiology [ 26 ], gastroenterology [ 35 ], neurosurgery [ 36 ], oral and maxillofacial surgery [ 37 ], ophthalmology [ 38 ], otolaryngology [ 39 ], orthopaedic surgery [ 22 ], plastic surgery [ 40 ], podiatry [ 41 ], pulmonology [ 42 ], radiation oncology [ 43 ], transplant surgery [ 44 ], urology [ 45 ], and vascular surgery [ 46 ].

Thanks to the different benefits that this technology could induce in the field, the main direct applications of 3D printing in the medical and clinical field are as follows [ 47 ]:

- Used for personalized presurgical/treatment and for preoperative planning. This will lead to a multistep procedure that, integrating clinical and imaging information, will determine the best therapeutic option. Several studies have demonstrated that patient-specific presurgical planning may potentially reduce time spent in the operating room (OR) and result in fewer complications [ 48 , 49 ]. Moreover, this may lead to reduced postoperative stays, decreased reintervention rates, and lower healthcare costs. The 3D-printing technology allows to provide to the surgeon a physical 3D model of the desired patient anatomy that could be used to accurately plan the surgical approach along with cross-sectional imaging or, alternatively, modelling custom prosthetics (or surgical tool) based on patient-specific anatomy [ 50 – 54 ]. In this way, a better understanding of a complex anatomy unique to each case is allowed [ 52 – 56 ]. Furthermore, the 3D printing gives the possibility to choose before the implantation the size of the prostheses components with very high accuracy [ 57 – 59 ].

- Customize surgical tools and prostheses: the 3D printing can be used to manufacture custom implants or surgical guides and instruments. Therefore, the customization of surgical tools and prostheses means a reduction of cost given by the additive manufacturing technique [ 52 – 54 , 60 ].

- Study of osteoporotic conditions: following a pharmacological treatment, 3D printing is useful in validating the results achieved by the patient. This enables a more accurate estimation of patientʼs bone condition and a better decision on the surgical treatment [ 15 ].

- Testing different device in specific pathways: a clear example is the reproduction of different vascular patterns to test the effectiveness of a cardiovascular system used to treat peripheral and coronary artery disease [ 61 ]. In this way, the 3D printing enables us to quickly produce prototypes of new design concepts or improvements to existing devices.

- Improving medical education: 3D-printed patient-specific models have demonstrated that they can increase performance and foster rapid learning [ 62 ], while significantly ameliorating the knowledge, management, and confidence of the trainees regardless of the area of expertise [ 8 ]. The benefits of 3D printing in education are the reproducibility and safety of the 3D-printed model with respect to the cadaver dissection, the possibility to model different physiologic and pathologic anatomy from a huge dataset of images, and the possibility to share 3D models among different institutions, especially with ones that have fewer resources [ 63 ]. 3D printers that have the capability to print with different densities and colours can be used to accentuate the anatomical details [ 64 , 65 ].

- Patient education: patient-centered cares makes patient education one of the top priorities for most healthcare providers. However, communicating imaging reports verbally or by showing patients their CT or MRI scans may not be effective; the patients may not fully understand 2D images representation of a 3D anatomy. On the contrary, 3D printing may improve the doctor-patient communication by showing the anatomic model directly [ 66 , 67 ].

- Storage of rare cases for educational purposes: this role is closely linked to the previous one. This allows the generation of a large dataset composed by datasets of patients affected by rare pathologies, allowing the training of surgeons in specific applications [ 52 – 54 ].

- Improve the forensic practice: in the courtroom, a 3D model could be used to easily demonstrate various anatomic abnormalities that may be difficult to jury members to understand using cross-sectional imaging [ 68 ].